Electroplatingyog txheej txheem ntawm tso ib txheej nyias ntawm cov hlau mus rau saum npoo ntawm cov yas lossis hlau los ntawm electrolysis.

Nws yog feem ntau siv rau kev kho kom zoo nkauj lossis kev tiv thaiv lub hom phiaj, xws li kev tiv thaiv corrosion, kev txhim kho hnav, thiab kev ua kom zoo nkauj.

Txoj kev loj hlob keeb kwm ntawm electroplating:

1800-1804: Cruikshank thawj zaug piav txog electroplating.

1805-1830: Brugnatelli invents electroplating.

1830-1840: Elkingtons patent ntau cov txheej txheem electroplating.

LUB SIJ HAWM ELECTROPLATING

LUB 20 XYOO TSHIAB

1900-1913: Electroplating dhau los ua kev tshawb fawb.

1914-1939: Lub ntiaj teb tsis quav ntsej electroplating.

1940-1969: The Gilded Revival.

Kev tsim kho niaj hnub thiab cov qauv hauv electroplating

Khoos phis tawj chips:

Electroless plating:

Hauv cov ntsiab lus, Electroplating muaj keeb kwm ntawm 218 xyoo txij li nws tau tsim los ntawm Italian inventor Luigi V. Brugnatelli hauv 1805.

Electroplating yog cov cuab yeej siv niaj hnub no thiab tau siv dav hauv ntau qhov chaw xws li cov khoom siv hauv tsev, kev lag luam tsheb, cov khoom siv hluav taws xob siab, thiab lwm yam. Cov khoom siv chromed lossis plated tuaj yeem txhim kho nws tag nrho cov khoom zoo, txuas ntxiv nws lub neej kev pab, thiab ua kom nws txoj kev lag luam muaj kev sib tw.

Muaj ntau hom electroplating, raws li hauv qab no;

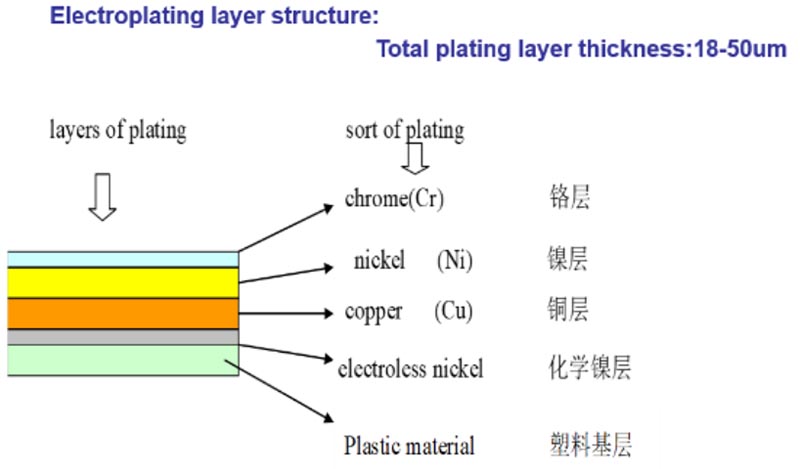

a, Chromium:Evaporate chromium hmoov rau ntawm cov hlau saum npoo los tsim cov tshuaj tiv thaiv corrosion-resistant chromium zaj duab xis, uas tuaj yeem tiv thaiv qhov chaw ntawm qhov chaw ntawm corrosion.

b, Nickel:Evaporate npib tsib xee hmoov rau ntawm cov hlau saum npoo los tsim cov yeeb yaj kiab corrosion-resistant nickel, uas ua rau lub neej kev pab cuam kom tau txais kev txuas ntxiv hauv ib txoj kev.

c, Tooj:Copper hmoov yog evaporated ntawm cov hlau nto kom tig mus rau hauv cov yeeb yaj kiab tiv thaiv corrosion, uas muaj peev xwm txhim kho qhov zoo ntawm cov khoom.

Peb tau sau qee cov ntsiab lus uas yuav pab koj nkag siab qhov zoo thiab qhov tsis zoo ntawm Electroplating kom meej.

Cov hauv qab no yog qhov zoo ntawm Electroplating;

A. Kev zoo nkauj zoo nkauj - Electroplating tuaj yeem siv los txhim kho cov tsos ntawm ntau yam khoom los ntawm kev ntxiv cov hniav zoo nkauj lossis ua haujlwm tiav.

B. Txhim khu durability - Electroplating tuaj yeem txhim kho kev ua haujlwm ntev ntawm cov khoom los ntawm kev ntxiv txheej tiv thaiv kev hnav thiab corrosion.

C. Nce conductivity- Electroplating tuaj yeem siv los txhim kho cov khoom siv hluav taws xob, ua kom nws tsim nyog rau kev siv hluav taws xob.

D. Customization- Electroplating tso cai rau ntau hom kev xaiv, suav nrog kev xaiv tiav, tuab, thiab xim.

E. Txhim kho muaj nuj nqi- Electroplating tuaj yeem txhim kho kev ua haujlwm ntawm ib qho khoom los ntawm kev ntxiv txheej nrog cov khoom tshwj xeeb, xws li nce hardness lossis lubrication.

Qhov tsis zoo ntawm Electroplating yog raws li nram no;

1. Tus nqi - Electroplating tuaj yeem yog cov txheej txheem kim, tshwj xeeb tshaj yog rau cov khoom loj lossis cov khoom siv.

2. Kev cuam tshuam ib puag ncig- Electroplating tuaj yeem tsim cov khoom pov tseg thiab cov khoom siv phom sij uas tuaj yeem tsim kev puas tsuaj rau ib puag ncig yog tias tsis muab pov tseg kom zoo.

3. txwv thickness- Lub thickness ntawm electroplated txheej yog txwv los ntawm lub thickness ntawm substrate thiab cov txheej txheem plating nws tus kheej.

4. Kev nyuaj siab - Electroplating tuaj yeem yog cov txheej txheem nyuaj uas xav tau cov cuab yeej tshwj xeeb thiab kev txawj ntse.

5. Muaj peev xwm rau qhov tsis xws luag- Electroplating tuaj yeem ua rau muaj teeb meem xws li hlwv, tawg, thiab tsis sib xws yog tias tsis ua kom zoo.

Nyob rau hauv tag nrho, electroplating technology boasts assorted nta xws li tag nrho cov tsos kev txhim kho, corrosion tiv thaiv, kev pab cuam lub neej extension, muaj zog durability, nqi-zoo, thiab cov khoom lag luam kev sib tw, uas yog vim li cas nws tau nrov ntawm cov kev lag luam sib txawv thoob plaws ntiaj teb.

About CheeYuen

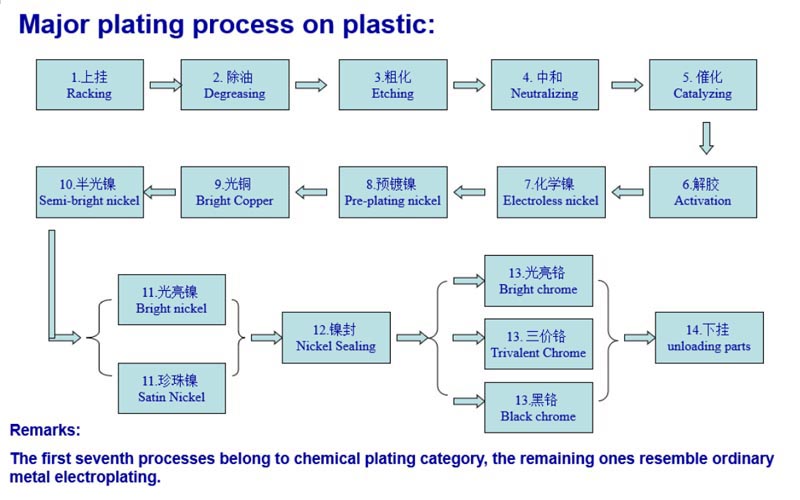

Tsim los ntawm Hong Kong xyoo 1969,CheeYuenyog ib lub chaw muab kev daws teeb meem rau kev tsim khoom yas thiab kho qhov chaw.Nruab nrog cov tshuab siab heev thiab cov kab ntau lawm (1 lub cuab yeej thiab kev txhaj tshuaj molding center, 2 electroplating kab, 2 painting kab, 2 PVD kab thiab lwm yam) thiab coj los ntawm ib tug cog lus pab neeg ntawm cov kws txawj thiab cov kws txawj,CheeYuen Surface Treatmentmuab ib tug turnkey tov rauchromed, pleev xim&PVD qhov chaw, los ntawm cov cuab yeej tsim rau kev tsim khoom (DFM) mus rau PPAP thiab nws thiaj li ua tiav cov khoom xa tuaj thoob plaws ntiaj teb.

Certified los ntawmTIAB SA 16949, ISO9001thiabISO 14001thiab audited nrogVDA 6.3thiabCSR, CheeYuen Surface Treatment tau dhau los ua tus neeg xa khoom dav dav thiab cov tswv yim sib koom tes ntawm ntau lub npe nrov thiab cov chaw tsim khoom hauv tsheb, khoom siv, thiab da dej industries, suav nrog Continental, ALPS, ITW, Whirlpool, De'Longhi thiab Grohe, lwm.

Puas muaj cov lus hais txog cov ncej no lossis cov ncauj lus uas koj xav pom peb npog yav tom ntej?

Xa email rau peb ntawm:peterliu@cheeyuenst.com

Post lub sij hawm: Oct-07-2023