Electroplating is a process of depositing a thin layer of metal onto a surface of plastic or metal through electrolysis.

It is commonly used for decorative or protective purposes, like anti-corrosion, wearability improvement, and aesthetics enhancement.

The development history of electroplating:

1800-1804: Cruikshank first describes electroplating.

1805-1830: Brugnatelli invents electroplating.

1830-1840: The Elkingtons patent several electroplating processes.

THE GILDED AGE OF ELECTROPLATING

THE 20TH CENTURY OVERHAUL

1900-1913: Electroplating becomes a science.

1914-1939: The world ignores electroplating.

1940-1969: The Gilded Revival.

Modern developments and trends in electroplating

Computer chips:

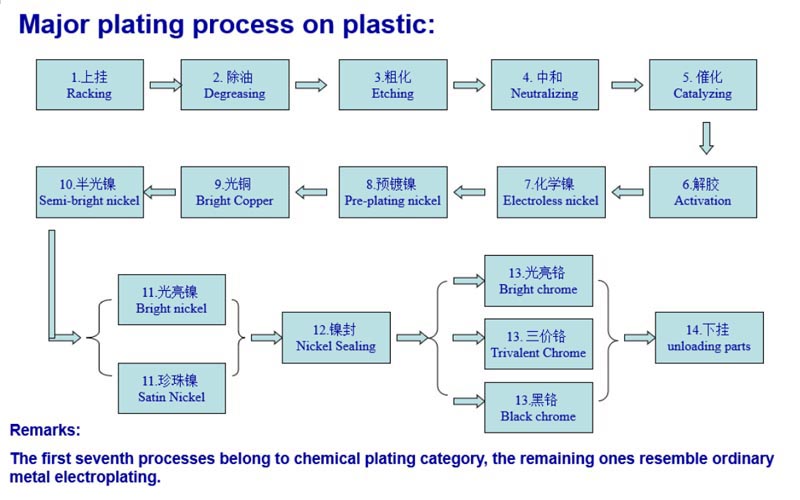

Electroless plating:

In summary, Electroplating has a history of 218 years since it was invented by Italian inventor Luigi V. Brugnatelli in 1805.

Electroplating is a matured technology today and has been widely used in various fields such as home appliances, the automotive industry, high-end electronic components, etc. The chromed or plated products can greatly enhance its overall surface quality, extend its service life, and heighten its market competitiveness.

There are a number of types of electroplating, as follows;

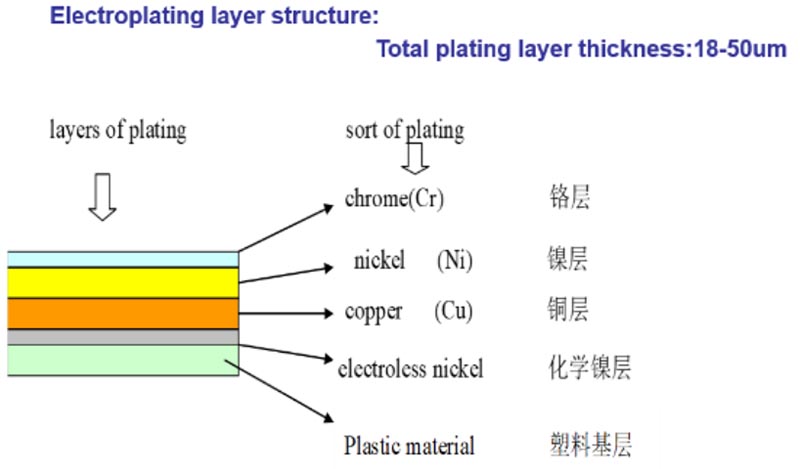

a, Chromium: Evaporate chromium powder on the metal surface to form a corrosion-resistant chromium film, which can protect the part’s surface from corrosion.

b, Nickel: Evaporate nickel powder on the metal surface to form a corrosion-resistant nickel film, which enables the part’s service life to gain an extension in a way.

c, Copper: Copper powder is evaporated on the metal surface to turn into a corrosion-resistant copper film, which is capable of improving the appearance quality of components.

We have collected some solid points that will help you understand the pros and cons of Electroplating in detail.

The followings are the advantages of Electroplating;

A. Improved aesthetics – Electroplating can be used to enhance the appearance of a variety of objects by adding a decorative or functional finish.

B. Enhanced durability – Electroplating can improve the durability of an object by adding a layer of protection against wear and corrosion.

C. Increased conductivity – Electroplating can be used to improve the conductivity of an object, making it more suitable for use in electrical applications.

D. Customization – Electroplating allows for a wide range of customization options, including the choice of finish, thickness, and color.

E. Improved function – Electroplating can improve the function of an object by adding a layer with specific properties, such as increased hardness or lubrication.

The disadvantages of Electroplating are as follows;

1. Cost – Electroplating can be a costly process, particularly for large or complex objects.

2. Environmental impact – Electroplating can produce hazardous waste and byproducts that can be harmful to the environment if not properly disposed of.

3. Limited thickness – The thickness of the electroplated layer is limited by the thickness of the substrate and the plating process itself.

4. Complexity – Electroplating can be a complex process that requires specialized equipment and expertise.

5. Potential for defects – Electroplating can result in defects such as blisters, cracks, and uneven coverage if not done properly.

On the whole, electroplating technology boasts assorted features such as overall appearance improvement, corrosion prevention, service life extension, strong durability, cost-effectiveness, and product market competitiveness, which is why it has been popularized among different industries across the globe.

About CheeYuen

Established in Hong Kong in 1969, CheeYuen is a solution provider for plastic part manufacturing and surface treatment. Equipped with advanced machines and production lines (1 tooling and injection molding center, 2 electroplating lines, 2 painting lines, 2 PVD line and others) and led by a committed team of experts and technicians, CheeYuen Surface Treatment provides a turnkey solution for chromed, painting & PVD parts, from tool design for manufacturing (DFM) to PPAP and eventually to finished part delivery across the globe.

Certified by IATF16949, ISO9001 and ISO14001 and audited with VDA 6.3 and CSR, CheeYuen Surface Treatment has become a widely-acclaimed supplier and strategic partner of a great number of well-known brands and manufacturers in automotive, appliance, and bath product industries, including Continental, ALPS, ITW, Whirlpool, De’Longhi and Grohe, etc.

Have comments regarding this post or topics that you would like to see us cover in the future?

Send us an email at : peterliu@cheeyuenst.com

Post time: Oct-07-2023