Chrome Plating Yas Txheej Txheem

CheeYuen - Cov chaw tsim khoom ua lag luam ntawm Electroplating hla yas puag ncig koj

Ua ibone-stop solution provider, CheeYuen boasts ntau yam seasoned technical talents thiab state-of-the-art chaw, ua rau peb muab high-zoo, check chrome-plated finishes ntawm yas Cheebtsam ntawm txawv qhov ntau thiab tsawg thiab duab.Lub caij no, peb kuj muaj peev xwm muab cov neeg siv khoom nrog cov kev pabcuam txiav, tsis hais qhov nyuaj lossis qhov loj ntawm cov khoom.

Tam sim no, peb tau muab cov khoom siv hluav taws xob thiab pleev xim yas tsheb thiab cov khoom siv hauv tsev kho kom zoo nkauj rau cov npe nrov xws li General motors, Ford, Fiat Chrysler, Volvo, Volkswagen, Tata, Mahindra, Toyota, Tesla, Delonghi, Grohe, American Standard, lwm.

Nyob rau hauv 54 xyoo dhau los, peb tau ua hauj lwm ntau tshaj 80 nto moo tsheb thiab cov neeg muas zaub nyob rau hauv 30 differenet lub teb chaws thiab cheeb tsam.

Peb tau txais kev qhuas thiab kev lees paub los ntawm cov neeg siv khoom raws li peb cov nqi sib tw, kev ua haujlwm zoo, thiab hloov pauv raws sijhawm raws sijhawm.

Thov hu rau peb hnub no kom paub ntau ntxiv txog pebyas chrome plating kev pab cuam thiab peb tuaj yeem pab koj ua tiav qhov zoo tshaj plaws rau koj cov khoom yas.

Chrome Plating ntawm Plastic Parts Services

CheeYuenmuaj ntau cov kab chrome tag nrho hauv ib lub ru tsev, muab cov kev xaiv hloov tau txawm tias qhov loj npaum li cas xav tau.Nrog kev xaiv xim tsis kawg, kev cai siv, kev ntxhib los mos thiab cov txheej txheem ruaj khov, peb txuas ntxiv nthuav peb lub peev xwm thiab muab peb cov neeg siv khoom nrog qhov yooj yim tshaj plaws rau lawv cov khoom.

Peb daim ntawv thov electroplating thiab txheej txheem tau ua kom zoo rau ntau tshaj 50 xyoo.Peb tsis tsuas yog hais txog kev ua pov thawj cov khoom zoo tshaj plaws rau peb cov neeg siv khoom, tab sis peb kuj sim peb qhov zoo tshaj plaws los tiv thaiv ib puag ncig kom ua tiav kev ruaj ntseg hauv peb lub lag luam.

Rau qhov kev pabcuam no, peb kuj muaj lub luag haujlwm rau qhov teeb meem ib puag ncig thiab ua raws li ROHS qhov xav tau los ntawm kev siv tshuaj lom neeg uas yog ib puag ncig freindly, uas yogtrivalent chromium plating (Trivalent Chromium)los yog (Cr3+) hauv peb cov txheej txheem.Peb pab neeg tau cog lus los muab peb cov neeg siv khoom nrog rau qib siab tshaj plaws ntawm kev txhawb nqa kev tshaj lij thiab ua tiav los txo cov kev puas tsuaj rau ib puag ncig.

Satin Chrome

Bright Nickel

Electroplating Qhov Rooj Trim nrog Trivalent Chrome

Auto Qhov Rooj Knob

Chrome Plating Yas Tsheb Qhov Chaw

Vim li cas thiaj xaiv peb?

Ib tus thawj coj thoob ntiaj teb hauv cov tuam txhab yas Chrome Plating! Kev xaiv peb cov khoom txhais tau tias xaiv ntau tshaj li ib feem;nws yog ib tug zoo meej blend ntawm innovation, zoo, thiab kev pab zoo heev.Peb ntseeg tau tias CheeYuen yas electroplating chaw tsim tshuaj paus yog tus neeg koom tes heev uas koj tab tom nrhiav.

Nrog ntau tshaj 54 xyoo ntawm kev paub hauv kev lag luam yas chrome plating

Peb muaj cov txheej txheem chrome plating tsis siv neeg

Peb muaj cov txheej txheem ntau lawm

Cov khoom zoo ua raws li cov qauv thoob ntiaj teb

Plating ntawm cov kab yas muaj peev xwm

Cov tshuaj tank dimenson rau tsis siv neeg plating kab yog 3000 * 1200 * 1500 MM

Kev daws tank dimenson rau kab plating yog 750 * 900 * 1500 MM

Nrog rau 1,500,000 Square meters ib xyoos twg ntawm cov yas plating muaj peev xwm

Hom plating thickness rau automotive hniav qhov chaw:

tooj liab 10-30um

Nickel 5-15um

Chrome 0.1-0.3um

Lus Cim: Raws li ib tus neeg siv khoom lossis ib feem requrement, peb tuaj yeem hloov kho ntawm txheej xav.

Cov khoom uas peb tuaj yeem ua phaj:

ABS

ABS / PC

PA 6

PAB 66

Electroplating tiav:

Bright chrome

Satin chrome

Dub chrome

Satin npib tsib xee

Chrome w / txhuam

Satin Nickel nrog txhuam

Chrome w / engraving

Kev xeem zoo

Txhawm rau kom cov khoom lag luam zoo thiab txhim khu kev ntseeg siab rau cov neeg siv khoom, peb muaj cov txheej txheem tshuaj xyuas uas siv los kuaj thiab tshuaj xyuas txhua tus txheej txheem, thiab tswj xyuas cov kev daws teeb meem zoo nrog chemistry thiab cov cuab yeej rau kev sim cov khoom zoo los ntawm

Cov neeg tseem nug:

Ntxuav

Tshem tawm cov roj, cov ntiv tes thiab cov impurities uas yuav ua rau tsis zoo rau qhov adhesion.

Kev npaj nto

Cov cua txias saum npoo, uas yog npaj los ntawm cov kua qaub tshwj xeeb, hloov cov

qauv ntawm cov yas nto nyob rau hauv xws li ib txoj kev uas muaj zog adhesion tau

nruab nrab ntawm nws thiab cov tshuaj nickel / tooj liab.Qhov kev txias no yog ib kauj ruam tseem ceeb hauv

kev kho mob ntawm cov yas rau electroplating.Cov kev tsis zoo uas cuam tshuam rau qhov tsis zoo adhesion feem ntau yog tshwm sim los ntawm qhov chaw txias.

Kev ua kom nto

Lub nto activator muaj palladium, uas txuas nws tus kheej mus rau saum npoo ntawm

cov yas.Tom qab ntawd cov khoom yog immersed nyob rau hauv ib tug accelerator kom tshem tawm a

tiv thaiv zaj duab xis los ntawm qhov chaw ntawm palladium.

Electroless npib tsib xee deposition

Tom qab ntawd lub tshuab ua kom muaj zog yog immersed nyob rau hauv ib qho electroless nickel tov, uas

tso ib txheej nyias ntawm cov hlau hla tag nrho cov yas substrate.Qhov no hlau

txheej ces dhau los ua tus neeg xyuas pib rau electroplating tom ntej.

Electrolytic tooj liab plating

Electrolytic plating, npib tsib xee thiab chrome

Kev ziab kom zoo ntawm cov resin

ABS yuav tsum tau qhuav ua ntej 2-3 teev ntawm 80-85 ° C ua ntej molding

Tsim kom muaj kev sib sau ceev

Cov khoom me me txog li 90 g: 5-7 secs

Cov khoom loj tshaj 90 g: mus txog 25 secs

Qhov kub thiab txias: 245-270 ° C

Qhov txias txias txias ua rau muaj kev ntxhov siab sab hauv, ua rau tsis sib xws etch thiab thermal cycling test tsis ua haujlwm

Kub yaj kub heev yuav ua rau cov khoom degrade thiab muab tsis zoo adhesion

Pwm qhov kub thiab txias: 65-80 ° C

Cov pwm txias dhau yuav ua rau cov yas flake.Cov khoom uas cuam tshuam cov pwm phab ntsa hardens thiab cov khoom kub hauv qab nws ntws, tsim kom muaj cov nyhuv ntawm daim tawv nqaij uas yuav ua rau delamination.

Lub sij hawm ua kom txias: mus txog 30 secs

Lub sijhawm txias txias ua rau muaj kev pheej hmoo ntawm kev ntxhov siab sab hauv

Highly polished pwm

Cov pwm tsis zoo tuaj yeem ua rau muaj qhov tsis xws luag hauv qhov molded

Cov ntaub ntawv noo noo<0.02%

Tsim rooj vag / hauv-pwm rau nro dawb-pwm ntws

Plateable ABS / PC

Muaj peev xwm rack

Kev nce nrov ntawm kev siv cov yas thiab cov yas sib xyaw ua ke hauv ntau cov txheej txheem tsim khoom kuj tau ua rau muaj kev thov ntau dua rau plating ntawm cov yas.Plating yas nrog ib tug hlau nto txhim khu cov tsos ntawm cov khoom thiab tsim lub tswv yim ntawm zoo dua.Yog li ntawd, nws yog feem ntau xaiv thaum lub siab zoo nkauj zoo nkauj.

Tsis tas li ntawd, plating ntawm cov yas tuaj yeem yog ib txoj hauv kev zoo los tiv thaiv lub substrate tiv thaiv lub zog ntawm corrosion thiab ua rau nws tiv taus ntau dua rau kev puas tsuaj los ntawm cov tshuaj siv hauv kev tsim khoom.Qee qhov xwm txheej, plating ntawm cov yas tuaj yeem ua rau muaj zog thiab hnav tsis kam ntawm substrate.

Raws li peb tau pom nyob rau hauv kev lag luam tsheb, ib qho txiaj ntsig tseem ceeb ntawm plating ntawm cov yas yog tias nws tuaj yeem txhim kho qhov pom ntawm cov substrate.Feem ntau cov khoom lag luam plastics zoo li muaj qhov tsis zoo.Thaum colorizing cov yas tuaj yeem ua rau nws pom kev zoo dua, nws tseem yuav tsis tsim qhov ci ci, ci ntsa iab uas ntau tus tswv khoom xav tau.Thaum plating nrog chrome tau ntev ua ib txoj hauv kev nrov hauv kev siv tsheb, cov teeb meem kev noj qab haus huv tshwm sim los ntawm cov txheej txheem hexavalent chromium plating tau coj ntau tus neeg muab kev pabcuam hlau los ntiav lwm txoj kev nyab xeeb, tshwj xeeb yog npib tsib xee plating.

Nrog rau qhov zoo li, plating rau yas muaj ob peb lwm yam txiaj ntsig rau cov khoom lub cev yam ntxwv:

Corrosion thiab tshuaj tiv thaiv: Plating ntawm cov yas tuaj yeem yog ib txoj hauv kev zoo los tiv thaiv lub substrate tiv thaiv lub zog ntawm corrosion thiab ua rau nws tiv taus ntau dua los ntawm cov tshuaj siv hauv kev tsim khoom.

Nce conductivity: Electroplating tseem tuaj yeem muab cov yas uas tsis yog cov khoom siv hluav taws xob muaj peev xwm ua hluav taws xob, cov cuab yeej muaj txiaj ntsig zoo rau cov tuam txhab hluav taws xob thiab cov khoom siv hauv tsheb, dav hlau thiab ntau yam khoom siv.Cov txheej hlau kuj tseem tuaj yeem cuam tshuam lub teeb uas ua rau lub teeb tsis zoo ntawm qhov chaw ntawm cov yas substrate thiab ua haujlwm tiv thaiv kev tiv thaiv cov pa phem thiab corrosion.Tsis tas li ntawd, metallization tuaj yeem pab tswj lub zog dissipation.

Ua kom muaj zog ntxiv:Electroplating tuaj yeem txhim kho ib feem ntawm lub zog tag nrho rau kev ua haujlwm ntev dua.Lub zog ntxiv no yog ib qho ntawm cov txiaj ntsig zoo tshaj plaws ntawm electroplating rau yas.Yog tias lub zog yog koj lub hom phiaj, nickel plating tuaj yeem yog qhov kev xaiv zoo vim tias nickel tuaj yeem tiv thaiv corrosion thiab txhim kho lub neej ntawm cov khoom.

Ruaj khov thiab tsis tshua muaj kev sib cuag:Ntxiv nrog rau kev tiv thaiv corrosion, plating kuj tuaj yeem txo qhov kev tiv thaiv kev tiv thaiv, yog li koj tuaj yeem ua rau kom muaj qhov tsis kam hnav, tshuaj thiab corrosion.

RFI thiab EMI tiv thaiv: Cov khoom siv hluav taws xob tso tawm hluav taws xob cuam tshuam (EMI) thiab xov tooj cua cuam tshuam (RFI), uas ua rau muaj teeb meem cuam tshuam thiab cov khoom siv tsis raug.Plating ntxiv txheej tiv thaiv los thaiv cov teeb meem EMI thiab RFI nthwv dej.

Plating rau cov yas yog ib txoj hauv kev zoo los ntxiv cov kav ntev hauv ntau qhov chaw sib txawv.Nws muaj kev tiv thaiv txhua hnub hnav los ntawm kev sib cuag, nrog rau kev tiv thaiv ntau dua tiv thaiv cov tshuaj lom neeg thiab cuam tshuam.Lub caij no, kev ncaj ncees ntawm cov qauv yog ib qho txiaj ntsig zoo hauv ntau daim ntawv thov, thiab ntxiv cov khoom siv rau cov yas yog ib txoj hauv kev zoo los ua kom cov qauv tsim tau yooj yim ntawm ib feem thaum tswj hwm tus nqi zoo ntawm kev tsim cov yas.

Muaj ntau yam kev mob thaum lub sij hawm molding, tuav, thiabplatingntawm cov khoom yas uas tuaj yeem ua rau muaj qhov tsis zoo hauv cov khoom tiav.Kev nkag siab txog cov laj thawj ntawm qee qhov kev tsis zoo tuaj yeem pab txhawm rau txheeb xyuas cov hauv paus hauv paus ntawm cov kev tsis zoo no thiab siv cov kev kho kom raug thoob plaws hauv cov khoom siv.

Splay

Splay yog ib pawg ntawm kev tawg, mars, lossis cov cim, pom ntawm ib qho plated.Txawm hais tias nws tsuas yog pom ib zaug plated, nws yog ua rau kuv cov teeb meem molding;trapped noo noo nyob rau hauv cov yas tuaj yeem tuaj rau saum npoo thaum txheej txheem plating, ua rau splay.

Flash

Flash yog ib tug protrusion ntawm yas ntawm ib feem ntug.Flash ntawm lub molded tivthaiv feem ntau mus unnoticed mus txog rau thaum tom qab cov tivthaiv tau plated, vim hais tias plating tsim nyob rau hauv lub protrusion.Qhov kev tsim cov phaj no tuaj yeem ua rau lub npoo ntawm qhov ntse, thiab tuaj yeem cuam tshuam rau qhov haum thiab zoo nkauj.Qhov kev tsis zoo no yog tshwm sim thaum lub sij hawm molding los ntawm cov yas ntau dhau los yog cov khoom tsis tawg ntawm pwm kom huv si.

Cov pob khaus

Cov pob khaus, zoo li cov tawv nqaij, yog cov hnab ntim cua hauv qab ntawm daim tawv nqaij - hauv cov ntsiab lus no, nruab nrab ntawm cov yas thiab cov hlau tso nyiaj.Zoo li splay, hlwv tuaj yeem tshwm sim los ntawm cov dej noo nyob hauv cov khoom siv molded;Txawm li cas los xij, cov hlwv kuj tuaj yeem tshwm sim thaum lub sij hawm plating, ntawm cov txheej txheem ntawm cov hlau tso nyiaj.Txhawm rau txiav txim siab qhov ua rau hlwv, txiav thiab tev lub hlwv rov qab.Yog hais tias nws yog los ntawm cov yas, thiab cov hauv qab ntawm lub hlwv muaj cov yas uas tau sib cais los ntawm cov khoom, lub hlwv tshwm sim los ntawm cov khoom ntub dej hauv molding.

Kos thiab Dents

Kos thiab dents tuaj yeem tshwm sim thaum lub sij hawm molding los yog tuav (ntawm cov nqaij nyoos los yog plated).Thaum lub plater feem ntau yuav ua qhov kev ntsuam xyuas tuaj ntawm cov khoom siv molded rau plating, qee qhov khawb lossis cov dents hauv cov yas yuav tsis pom tseeb tam sim ntawd, lossis cov khoom nyoos yuav raug khawb thaum tuav.Kos thiab dents tuaj yeem tshwm sim thaum tuav cov phaj tom qab;tej zaum nws yuav qhia tau los ntawm qhov tob ntawm khawb los yog dent thiab plating deposit nyob rau hauv lub cheeb tsam seb lub imperfection yog superficial los yog nyob rau hauv lub hauv paus khoom.

Qhuav cia

Qhuav cia yog marred plating thiab nws tshwm sim thaum lub sij hawm plating txheej txheem thaum ib feem yuav qhuav heev ntawm cov hlau deposits.Qhov no tuaj yeem zam tau los ntawm kev ua tib zoo tswj cov txheej txheem plating.

Warp

Warp yog qhov sib txawv ntawm qhov sib txawv ntawm cov khoom thiab tuaj yeem tshwm sim ntawm ob peb theem ntawm cov txheej txheem tsim khoom.Moulding yuam kev tuaj yeem ua rau warp, thiab warp kuj tuaj yeem tshwm sim los ntawm qhov kub thiab txias, racking qhov tsis raug, lossis ua haujlwm tsis zoo.

Hla lub phaj

Hla lub phaj yog qhov tsis muaj plating ntawm qhov chaw - cov khoom siv hauv paus raug nthuav tawm.Nws tuaj yeem tshwm sim los ntawm cov kab mob sib kis ntawm qhov chaw, uas tiv thaiv cov plating los ntawm kev tso rau ntawm qhov chaw.Xyuas kom meej tias cov khoom nyoos raug tswj xyuas kom zoo thiab khaws cia tsis muaj cov kab mob ntawm qhov chaw tuaj yeem txo qhov tshwm sim ntawm hla lub phaj.

Acrylonitrile-Butadiene-Styrene (ABS)

Acrylonitrile butadiene styrene (ABS) yog cov thermoplastic polymer dav suav tias yog thawj cov khoom siv yas siv rau electroplating.Cov txheej txheem tau tsim tshwj xeeb rau kev lag luam tsheb hauv xyoo 1960 thiab tseem siv niaj hnub no.

Yog - koj tuaj yeem tau txais koj cov khoom yas kho hauv cov xim zoo li chrome (hlau) xim.Peb cov xim tiav suav nrog electroplating, yog li nws muaj zog dua thiab ruaj khov dua li cov tshuaj tsuag ib leeg.Yog li yog tias koj xav tau koj cov yas dashboard kom tiav hauv cov xim tab sis tseem muaj qhov tob thiab luster ntawm chrome tiav - koj tuaj yeem!

| Txheej txheem | Kev piav qhia |

| Yas Chroming Txheej Txheem / es rau cov khoom tsis yog xim hlau (thiab tsis yog ABS *). | Metallising txheej txheem ua ntej.Tom qab ntawd 'Triple Chrome' plated. Daim iav chrome tiav. Muaj zog tooj liab, npib tsib xee, chrome qauv |

| Txheej txheem rau ABS * yas | Cov txheej txheem tshwj xeeb ntawm kev npaj, tom qab ntawd 'Triple Chrome' plated.Daim iav chrome tiav. Muaj zog tooj liab, npib tsib xee, chrome qauv. |

| Vacuum Txheej (Nqus Metallising) | Ib txheej "chrome-zoo li" (tsis yog chrome tiag) ntawm lub tshuab nqus tsev. Bright, nyias, silvery tiav. Nyias phab ntsa txheej - tuaj yeem ua rau puas tsuaj.Tej zaum yuav tsim nyog rau qee lub hom phiaj. |

| Txau chrome | Painted (raws li ib tug hybrid ntawm xim & tshuaj tiav). Nws tuaj yeem yog qhov sib tw ze rau chrome tab sis muaj kev hloov pauv vim yog xim sib xyaw thiab cov txheej txheem. Durability zoo ib yam li 2-pob xim. |

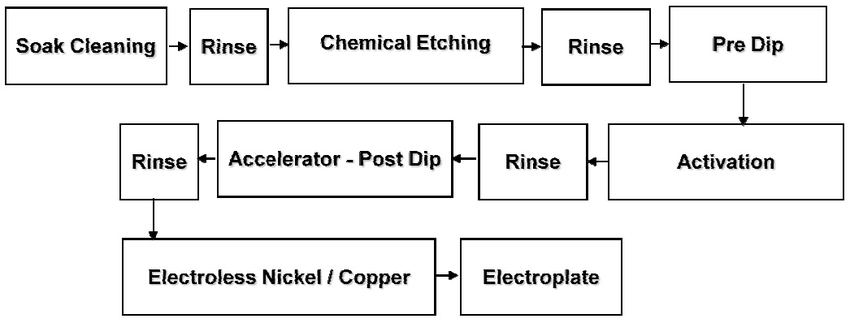

Chrome Yas Plating txheej txheem

Kauj Ruam 1 - Etching.Peb muab tso rau hauv ib lub tank uas muaj cov concentrated sulfuric thiab chromic acids.

Kauj Ruam 2 – Neutralization.

Kauj Ruam 3 - Catalyzing thiab Accelerating.

Kauj Ruam 4 - Electro-tsawg plating.

Kauj Ruam 5 - Electro Plating.

Kauj Ruam 6 - Kev Tshuaj Xyuas Zoo.

Tiag tiag chrome, koj feem ntau twv yuav raug hu tuaj yeem polish thiab ntub xuab zeb los ua kom tiav.Fake chrome (yas zaj duab xis los yog chrome plated) tuaj yeem polished, tab sis nyob rau hauv lub lightest ntawm zam.

Zoo li hlau,yas kuj tuaj yeem ua chrome plated.Rau txoj kev no, koj yuav tsum xa tawm cov khoom yas uas koj xav ntxiv chrome rau plating.Covplating tuam txhabyuav tsho koj feem hauv cov khaubncaws sab nraud povtseg ntawm npib tsib xee thiab tooj liab ua ntej nws mam li siv cov chrome.