Production Equipment

Equipped with advanced machines and production lines (1 tooling and injection molding center, 2 electroplating lines, 2 painting lines, 2 PVD line and others) and led by a committed team of experts and technicians, CheeYuen Surface Treatment provides a turnkey solution for chromed, painting & PVD parts, from tool design for manufacturing (DFM) to PPAP and eventually to finished part delivery across the globe.

Electroplating Workshop

Electroplating Workshop

Copper Plating Process

Eletroplating Tank

Circular Plating Line

Matt Chrome Process

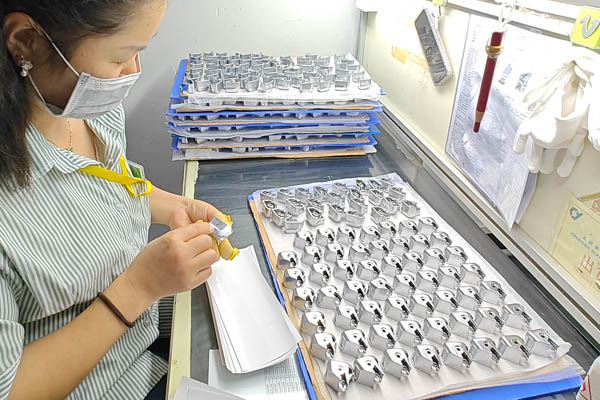

Mounting Part onto Jig

Parts to Be Plated

Plated Parts on Plastics

Plating Copper Process

Plating tank

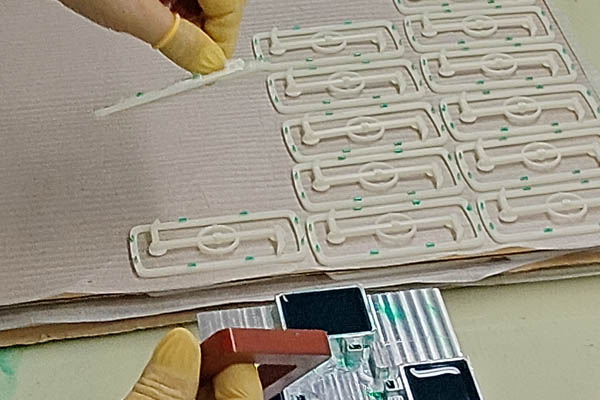

Resin Process

Unloading Parts from the Rack

Full Inspection

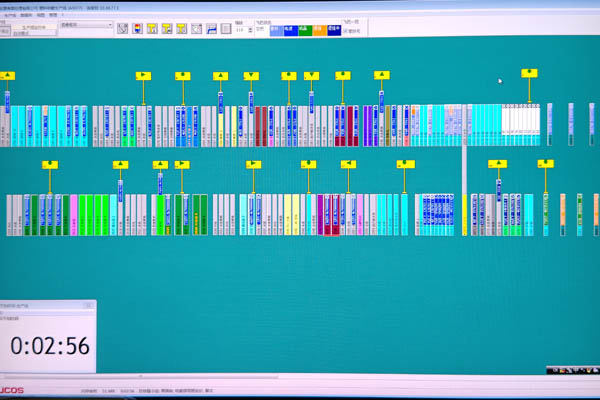

German AUCOS Control System

Inspection & Package

Loading Parts

Back-End Workshop

Assembly Operation

Assembly Shop

Auto Knob Package

Automatic De-Gating Fixture

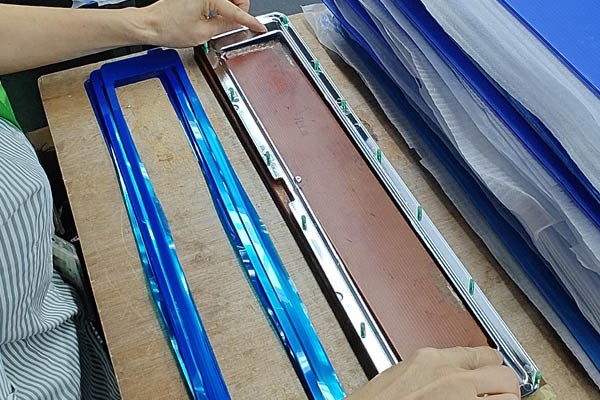

Blue Film Assembly

Buffing for Auto Lever

Engraving Process

Film Assembly onto Auto Knob

Knob Assembly

Masking Process for Auto Bezel

PAD Printing for Grohe Bathroom Components

Polishing for Auto Trim

Painting Workshop

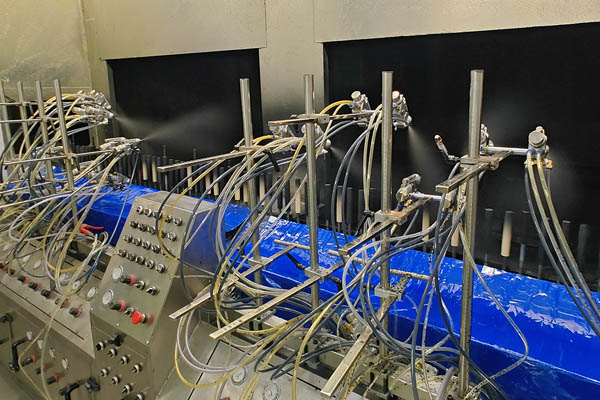

Japanese Anest Iwata Spay Guns

Painting Control Equipment

Painting Guns

Painting Workshop

UV Painting Room

UV Painting Room

UV Painting Room

Injection Workshop

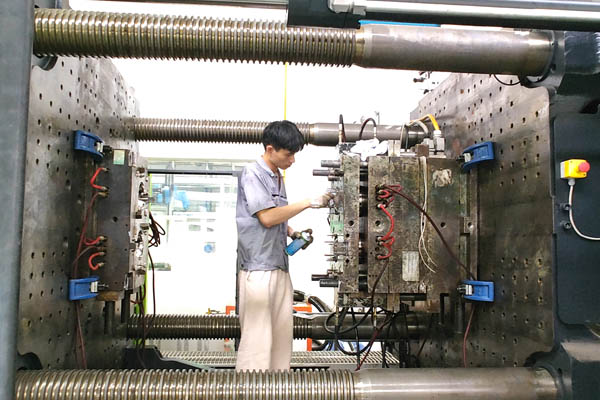

750t Injection Machine

Injection Workshop

Centralized Feeding System

Japanese Yushin Robot Arm

Molding Injection Machines

Molding Machines

Molding Shop

Tool Maintance

Molds

Tools

Mold Repair Workshop

Molded Bezel De-Gating

Film Assembly for Auto Handle

Auto Door Handle De-Gating