Chrome Plating Pulasitiki Njira

CheeYuen- Wopanga Wotsogola wa Electroplating pa Plastic Around You

Kukhala awopereka njira imodzi, CheeYuen amadzitamandira zosiyanasiyana luso luso ndi zipangizo zamakono, kutithandiza kupereka apamwamba, cholimba chrome-yokutidwa amalizitsa pa pulasitiki zigawo zikuluzikulu ndi maonekedwe osiyanasiyana.Pakadali pano, timathanso kupatsa makasitomala ntchito yopangidwa mwaluso, mosasamala kanthu za zovuta kapena kukula kwa gawolo.

Pakadali pano, takhala tikupereka ma electroplating ndi penti zapulasitiki zamagalimoto ndi zida zapanyumba zamagalimoto odziwika bwino monga General motors, Ford, Fiat Chrysler,Volvo, Volkswagen, Tata, Mahindra, Toyota, Tesla, Delonghi, Grohe,American Standard, ndi zina.

Pazaka 54 zapitazi, tatumikira makasitomala opitilira 80 odziwika agalimoto ndi zida zamagetsi m'maiko 30 ndi zigawo.

Talandira kutamandidwa kwakukulu ndi kuzindikirika ndi makasitomala malinga ndi mtengo wathu wampikisano, magwiridwe antchito olimba, osinthika komanso kutumiza nthawi.

Chonde titumizireni lero kuti mudziwe zambiri za athupulasitiki chrome plating utumiki ndi momwe tingakuthandizireni kuti mukwaniritse bwino kwambiri zigawo zanu zapulasitiki.

Chrome Plating pa Ntchito Zazigawo Zapulasitiki

CheeYuenili ndi mizere ingapo ya chrome pansi pa denga limodzi, imapereka zosankha zosinthika mosasamala kanthu za kukula kwa gawo lomwe likufunika.Pokhala ndi mitundu yosatha yamitundu, machitidwe, mapangidwe ndi chitukuko chokhazikika, tikupitiriza kukulitsa luso lathu ndikupatsa makasitomala athu kusinthasintha kwakukulu kwa zinthu zawo.

Ntchito yathu yopangira ma electroplating yakonzedwa kwazaka zopitilira 50.Sitikungogogomezera kutsimikizira chinthu chabwino kwambiri kwa makasitomala athu, koma timayesetsanso kuteteza chilengedwe kuti tikwaniritse bizinesi yathu.

Pantchitoyi, timayang'aniranso za chilengedwe ndipo timagwirizana ndi zofunikira za ROHS pogwiritsa ntchito mankhwala omwe si achilengedwe, omwe nditrivalent chromium plating (Trivalent Chromium)kapena (Cr3+) munjira yathu.Gulu lathu ladzipereka kupatsa makasitomala athu chithandizo chapamwamba chaukadaulo ndikukwaniritsa kuchepetsa kuwononga chilengedwe.

Satin Chrome

Nickel Wowala

Electroplating Door Trim yokhala ndi Trivalent Chrome

Auto Door Knob

Zida Zagalimoto Zapulasitiki za Chrome Plating

N'chifukwa Chiyani Mutisankhe?

Mtsogoleri Wapadziko Lonse M'makampani Opaka Pulasitiki Chrome! Kusankha zinthu zathu kumatanthauza kusankha zambiri osati chigawo chimodzi;ndi kuphatikiza kwatsopano kwatsopano, mtundu, ndi ntchito yabwino kwambiri.Tili otsimikiza kuti CheeYuen pulasitiki electroplating wopanga ndi bwenzi kwambiri mgwirizano kuti mukuyang'ana.

Ndili ndi zaka zopitilira 54 mumakampani opanga mapulasitiki a chrome

Tili ndi njira yopangira chrome yokha

Tili ndi ndondomeko yathunthu yopanga

Ubwino wa malonda umagwirizana ndi miyezo yapadziko lonse lapansi

Kuyika pamzere wa pulasitiki Maluso

Njira yothetsera tanki ya mzere wodziwikiratu ndi 3000 * 1200 * 1500 MM.

Njira yothetsera tanki ya mzere wozungulira wozungulira ndi 750 * 900 * 1500 MM.

Ndi 1,500,000 Square metres pachaka pa plating pulasitiki mphamvu

Kukula kwapang'onopang'ono kwa zigawo zokongoletsa zamagalimoto:

Mkuwa 10-30 mm

Nickel 5-15um

Chrome 0.1-0.3um

Ndemanga: Malinga ndi kasitomala kapena gawo lofunikira, titha kusintha malingaliro opaka.

Zinthu zomwe titha kuziyika:

ABS

ABS / PC

PA6

PA66

Zomaliza za Electroplating:

Chowala chowala

Satin chrome

Black chrome

Nickel ya satin

Chrome ndi / brushing

Nickel ya Satin ndi / brushing

Chrome w / engraving

Kuyesa Kwabwino

Kuwonetsetsa kuti zinthu zili bwino komanso kukulitsa chidaliro chamakasitomala, tili ndi makina owunikira omwe amagwiritsa ntchito kuyesa ndikusanthula njira iliyonse, ndikuwongolera njira zothetsera mankhwala pogwiritsa ntchito chemistry ndi zida zoyezera momwe zinthu ziliri.

Anthu Anafunsanso:

Kuyeretsa

Amachotsa mafuta, zidindo za zala ndi zonyansa zomwe zingakhudze kwambiri zomatira.

Kukonzekera pamwamba

The pamwamba conditioner, amene anakonza kuchokera wapadera zidulo, amasintha

kapangidwe ka pulasitiki pamwamba m'njira yoti kumamatira mwamphamvu kungapezeke

pakati pake ndi mankhwala nickel/copper.Kukonzekera uku ndi sitepe yofunika kwambiri

mankhwala apulasitiki a electroplating.Zolakwika zokhudzana ndi kusamata bwino zimayamba chifukwa cha mawonekedwe a pamwamba.

Kutsegula pamwamba

The pamwamba activator lili palladium, amene amadziphatika pamwamba pa

pulasitiki.Chigawocho chimamizidwa mu accelerator kuchotsa a

filimu yoteteza kuchokera pamwamba pa palladium.

Electroless nickel deposition

The adamulowetsa chigawo chimodzi ndiye kumizidwa mu electroless faifi tambala njira, amene

amaika chitsulo chopyapyala pagawo lonse la pulasitiki.Chitsulo ichi

wosanjikiza ndiye amakhala kondakitala wotsatira electroplating.

Electrolytic mkuwa plating

Electrolytic plating, nickel ndi chrome

Kuyanika koyenera kwa utomoni

ABS iyenera kuumitsidwa kale kwa 2-3 hrs pa 80-85 °C isanapangidwe.

Kuthamanga koyenera kodzaza

Zigawo zazing'ono mpaka 90 g: 5-7 secs

Zigawo zazikulu zopitilira 90 g: mpaka masekondi 25

Kutentha koyenera kusungunuka: 245-270 ° C

Kutentha kozizira kwambiri kumayambitsa kupsinjika kwamkati, zomwe zimapangitsa kuti pakhale kulephera kwapang'onopang'ono komanso kulephera kwapang'onopang'ono

Kutentha kwambiri kusungunuka kungapangitse kuti zinthuzo ziwonongeke komanso kuti zisamamatire bwino

Kutentha koyenera kwa nkhungu: 65-80 ° C

Kuzizira kwambiri kumapangitsa pulasitiki kuphulika.Zinthu zomwe zimagunda khoma la nkhungu zimauma ndipo zinthu zotentha pansi pake zimatuluka, ndikupanga khungu lapamwamba lomwe lingayambitse delamination.

Nthawi yoziziritsa yoyenera: mpaka masekondi 30

Kuzizira nthawi yayitali kumawonjezera chiopsezo cha zovuta zamkati

Chikombole chopukutidwa kwambiri

Kusauka kwa nkhungu kungayambitse zolakwika mu gawo lopangidwa

Chinyezi chakuthupi<0.02%

Pangani zitseko / mu-ziumba kuti muzitha kuyenda mopanda nkhungu

ABS / PC yokhazikika

Wokonzeka rack

Kuchulukirachulukira kwa kugwiritsa ntchito mapulasitiki ndi ma pulasitiki ophatikizika m'njira zosiyanasiyana zopangira kwadzetsanso kufunikira kokulirapo kwa pulasitiki.Kuyika pulasitiki ndi chitsulo pamwamba kumapangitsa kuti zinthu ziwoneke bwino ndipo zimapanga chithunzithunzi chapamwamba.Chotsatira chake, nthawi zambiri chimasankhidwa pamene mawonekedwe okongoletsera kwambiri akufunidwa.

Kuphatikiza apo, plating pa pulasitiki itha kukhala njira yabwino yotetezera gawo lapansi ku mphamvu za dzimbiri ndikupangitsa kuti lisawonongeke ndi mankhwala omwe amagwiritsidwa ntchito popanga.Nthawi zina, plating pa pulasitiki akhoza kuonjezera mphamvu ndi kuvala kukana kwa gawo lapansi.

Monga tawonera m'makampani opanga magalimoto, phindu lofunika kwambiri lopaka pulasitiki ndikuti limatha kukulitsa mawonekedwe a gawo lapansi.Mapulasitiki ambiri ogulitsa mafakitale amakhala ndi mapeto osowa.Ngakhale kukongoletsa pulasitiki kumapangitsa kuti ikhale yowoneka bwino, sikungapange mawonekedwe owala, onyezimira omwe eni ake ambiri amafuna.Ngakhale kupukutira ndi chrome kwakhala njira yodziwika bwino pamagalimoto, zoopsa zomwe zingabwere chifukwa cha plating ya chromium yachititsa kuti ambiri omaliza zitsulo agwiritse ntchito njira zina zotetezeka, makamaka plating ya nickel.

Pamodzi ndi mawonekedwe, kuyika papulasitiki kumapereka maubwino ena angapo pamawonekedwe a chinthucho:

Corrosion ndi Chemical resistance: Kuyika pa pulasitiki kungakhale njira yabwino yotetezera gawo lapansi ku mphamvu za dzimbiri ndikupangitsa kuti lisawonongeke ndi mankhwala omwe amagwiritsidwa ntchito popanga.

Kuwonjezeka kwa conductivity: Electroplating ingaperekenso pulasitiki yopanda pulasitiki yokhoza kuyendetsa magetsi, katundu wofunika kwambiri kwa opanga zida zamagetsi ndi zigawo zomwe zimagwiritsidwa ntchito pamagalimoto, ndege ndi zinthu zina zambiri.Chophimba chachitsulo chimathanso kuwunikira kuwala komwe kungawononge kutali ndi gawo lapansi la pulasitiki ndikukhala ngati chotchinga choteteza ku mpweya woipa ndi dzimbiri.Kuonjezera apo, metallization ingathandize kuthetsa kutaya mphamvu.

Kuchulukitsa mphamvu zamapangidwe:Electroplating imatha kupititsa patsogolo mphamvu ya gawo lonse kuti likhale lolimba.Mphamvu yowonjezera iyi ndi imodzi mwamaubwino apamwamba a electroplating papulasitiki.Ngati cholinga chanu ndi mphamvu, nickel plating ikhoza kukhala chisankho chabwino chifukwa faife imatha kukana dzimbiri ndikusintha moyo wazinthu.

Kusagwirizana kokhazikika komanso kocheperako:Kuphatikiza pa kukana kwa dzimbiri, plating imathanso kuchepetsa kukana kukhudzana, kotero mutha kuwonjezera kukana kwa gawolo kuti isavale, mankhwala ndi dzimbiri.

Chitetezo cha RFI ndi EMI: Zipangizo zamagetsi zimatulutsa kusokoneza kwamagetsi (EMI) ndi kusokoneza kwa ma radio frequency (RFI), zomwe zimathandizira kusokonezeka kwa ma siginecha ndi kuwonongeka kwa zida.Plating amawonjezera chitetezo kuti atseke mafunde owopsa a EMI ndi RFI.

Kuyika pa pulasitiki ndi njira yabwino yowonjezerera kulimba m'malo osiyanasiyana.Amapereka chitetezo cha zovala za tsiku ndi tsiku kuti asagwirizane, komanso chitetezo champhamvu kwambiri ku mankhwala ndi kusokoneza.Pakalipano, kukhulupirika kwapangidwe ndi phindu lalikulu muzogwiritsira ntchito zambiri, ndipo kuwonjezera ma conductivity ku pulasitiki ndi njira yabwino yowonjezeretsa kusinthasintha kwa kamangidwe ka gawo ndikusunga mtengo wamtengo wapatali wa zomangamanga za pulasitiki.

Pali zinthu zosiyanasiyana pa kuumba, kusamalira, ndiplatingza zida zapulasitiki zomwe zitha kubweretsa zolakwika pazomaliza.Kumvetsetsa zomwe zimayambitsa zina mwazolakwika kungathandize kuzindikira zomwe zimayambitsa zolakwikazi ndikukhazikitsa njira zowongolera panthawi yonseyi.

Masewera

Splay ndi gulu la zopuma, mars, kapena zizindikiro, zowonekera pagawo lopukutidwa.Ngakhale zimangowonekera kamodzi kokha, zimayambitsa zovuta zanga;Chinyezi chotsekeredwa mu pulasitiki chimatha kubwera pamwamba pakupanga plating, ndikuyambitsa splay.

Kung'anima

Kung'anima ndi kutulutsa kwa pulasitiki kumbali ina.Kung'anima pa chigawo chowumbidwa nthawi zambiri sichidziwika mpaka chigawocho chitakutidwa, chifukwa plating imamangirira pamawonekedwewo.Kupanga mbale iyi kungapangitse m'mphepete mwa gawolo kukhala lakuthwa, komanso kusokoneza kukwanira ndi mawonekedwe.Kupanda ungwiro kumeneku kumayambitsidwa ndi pulasitiki yochulukirapo kapena chigawocho sichimachoka mu nkhungu bwino.

Matuza

Matuza, monga momwe khungu limakhalira, ndi matumba a mpweya pansi pa khungu - mu nkhaniyi, pakati pa pulasitiki ndi chitsulo.Monga splay, matuza amatha kuyambitsidwa ndi chinyezi chotsekeredwa mkati mwa chigawo chopangidwa;Komabe, matuza amathanso kuyambitsidwa panthawi yopaka, pakati pa zigawo zachitsulo.Kuti mudziwe chomwe chimayambitsa matuza, dulani ndikuchotsa chithuzacho.Ngati zimachokera ku pulasitiki, ndipo pansi pa chithuzacho chimakhala ndi pulasitiki yomwe yalekanitsidwa ndi chigawocho, chithuzacho chimachokera ku chinyontho chomwe chimamangidwa.

Zokwangula ndi Madontho

Kukwapula ndi madontho amatha kupangika pakumangirira kapena kugwira (kwa gawo laiwisi kapena lopukutidwa).Ngakhale mbale nthawi zambiri imachita kafukufuku wobwera pazigawo zowumbidwa kuti zipangike, zingwe kapena zobowola mu pulasitiki sizingawonekere nthawi yomweyo, kapena ziwiya zitha kukwapulidwa pogwira.Zing'onozing'ono ndi zowonongeka zimatha kuchitikanso panthawi yogwiritsira ntchito positi;zitha kudziwika ndi kuya kwa kukanda kapena kubowoka ndi kuyikapo pagawolo ngati kupanda ungwiro kuli kwachiphamaso kapena m'munsi.

Dry Down

Kuwuma pansi kumakhala kowonongeka ndipo kumachitika panthawi ya plating pamene gawolo limakhala louma kwambiri pakati pa zitsulo.Izi zitha kupewedwa mwa kuwongolera mosamalitsa ntchito ya plating.

Warp

Warp ndi kupotoza kwa dimensional kwa gawo ndipo kumatha kuchitika pang'onopang'ono popanga.Zolakwika zomangira zimatha kuyambitsa kupindika, komanso kutha kwa zingwe kumatha chifukwa cha kutentha kwambiri, kugwedeza gawo molakwika, kapena kusagwira bwino gawolo.

Dumpha mbale

Skip plate ndi kusakhalapo kwa plating pamwamba - zinthu zoyambira zimawonekera.Zitha kuyambitsidwa ndi zonyansa pamtunda wa gawolo, zomwe zimalepheretsa kuti plating isapangidwe pamwamba pa gawolo.Kuwonetsetsa kuti zida zaiwisi zasamalidwa bwino komanso kukhala zopanda zoyipitsidwa pamtunda kungachepetse kupezeka kwa skip plate.

Acrylonitrile-Butadiene-Styrene (ABS)

Acrylonitrile butadiene styrene (ABS) ndi polima ya thermoplastic yomwe imadziwika kuti ndi pulasitiki yoyamba yomwe imagwiritsidwa ntchito popanga electroplating.Njirayi idapangidwira makampani opanga magalimoto m'ma 1960 ndipo ikuchitikabe mpaka pano.

Inde - mutha kupangira zida zanu zapulasitiki mumitundu ya chrome-ngati (chitsulo).Kumaliza kwathu kwa utoto kumaphatikizapo electroplating, kotero ndikokhazikika komanso kolimba kuposa kumaliza kutsitsi kokha.Chifukwa chake ngati mungafune kuti dashboard yanu yapulasitiki ikhale yomalizidwa mumtundu koma kukhala ndi kuya ndi kukongola kwa chrome - mutha!

| Njira | Kufotokozera |

| Pulasitiki Chroming Process/es ya magawo omwe si achitsulo (ndi omwe si ABS*). | Metallization ndondomeko choyamba.Kenako 'Triple Chrome' idakutidwa. Mirror chrome kumaliza. Mkuwa wamphamvu, nickel, kapangidwe ka chrome |

| Njira yamapulasitiki a ABS * | Njira yapadera yokonzekera, kenako 'Triple Chrome' yodzaza.Mirror chrome kumaliza. Mkuwa wamphamvu, nickel, kapangidwe ka chrome. |

| Kupaka zitsulo (Vacuum Metallising) | Chophimba "chofanana ndi chrome" (osati chrome yeniyeni) kudzera muukadaulo wa vacuum. Zowala, zoonda, zasiliva. Kupaka khoma lopyapyala - kumatha kuwonongeka.Zitha kukhala zokwanira pazifukwa zina. |

| Phulani chrome | Zopaka utoto (zotengera mtundu wosakanizidwa wa utoto & kumaliza kwamankhwala). Itha kukhala yofananira ndi chrome koma imatha kusiyanasiyana chifukwa cha kusakanikirana kwamitundu ndi njira. Kukhalitsa kumafanana ndi utoto wapaketi 2. |

Njira Yopangira Pulasitiki ya Chrome

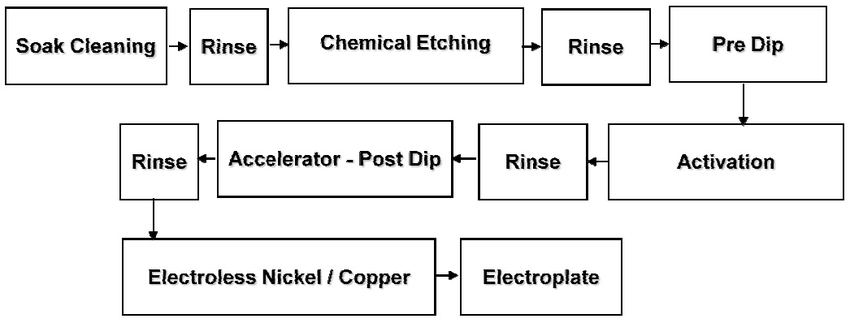

Khwerero 1 - Kusintha.Timamiza gawolo mu thanki yomwe imakhala ndi zosakaniza za sulfuric ndi chromic acid.

Gawo 2 - Neutralization.

Khwerero 3 - Kuwongolera ndi Kufulumizitsa.

Khwerero 4 - Kuyika kwa Electro-less Plating.

Gawo 5 - Electro Plating.

Khwerero 6 - Kuyang'anira Ubwino.

Chrome weniweni, mutha kupukuta ndi mchenga wonyowa kuti mubwezeretse kumaliza.Chrome yabodza (filimu ya pulasitiki kapena chrome yokutidwa) imatha kupukutidwa, koma mopepuka kwambiri.

Monga chitsulo,pulasitiki imathanso kukhala ndi chrome.Panjira iyi, muyenera kutumiza zida zapulasitiki zomwe mukufuna kuwonjezera chromium kuti mupange zokutira.Thekampani yopanga platingadzayala gawo lanu mu zigawo za faifi tambala ndi mkuwa musanagwiritse ntchito chrome.