Inkqubo yePlastiki yeChrome

CheeYuen- Umenzi oKhokelayo we-Electroplating ngaphezulu kwePlastiki Ekujikelezileyo

Ukuba aumboneleli wesisombululo one-stop, I-CheeYuen iqhayisa ngeetalente zobugcisa ezahlukeneyo kunye nezibonelelo zanamhlanje, ezisenza sikwazi ukubonelela ngekhwalithi ephezulu, ehlala i-chrome-plated finishes kumalungu eplastiki yobukhulu obuhlukeneyo kunye neemilo.Ngeli xesha, siyakwazi ukubonelela abathengi ngenkonzo eyenziweyo, ngaphandle kokuntsonkotha okanye ubungakanani becandelo.

Okwangoku, besibonelela nge-electroplating kunye nokupeyinta iimoto zeplastiki kunye nezixhobo zokuhombisa izixhobo zasekhaya kwiimveliso ezaziwayo ezifana neGeneral motors, iFord, iFiat Chrysler, iVolvo, iVolkswagen, iTata, iMahindra, iToyota, iTesla, iDelonghi, iGrohe, iAmerican Standard, njl.

Kule minyaka ingama-54 idlulileyo, siye sakhonza ngaphezu kwe-80 yabathengi abadumileyo beemoto kunye nezixhobo zombane kumazwe angama-30 kunye nemimandla.

Sizuze indumiso ephezulu kunye nokuqondwa ngabathengi ngokwexabiso lethu elikhuphisanayo, ukusebenza okuqinileyo komgangatho, kunye nokuguquguquka kunye nokufika ngexesha.

Nceda uqhagamshelane nathi namhlanje ukuze ufunde ngakumbi malunga wethuinkonzo yeplastiki ye-chrome plating kwaye sinokukunceda njani ukuba ufezekise ukugqiba okugqibeleleyo kumacandelo akho eplastiki.

Ukufakwa kweChrome kwiiNkonzo zePlastiki

CheeYueninemigca emininzi yechrome yonke phantsi kophahla olunye, inika iinketho eziguquguqukayo nokuba yeyiphi na indawo efunekayo.Ngokukhetha umbala ongapheliyo, izicelo zesiko, ukuthungwa kunye nophuhliso lwenkqubo ezinzileyo, siyaqhubeka nokwandisa amandla ethu kwaye sinikeze abathengi bethu ukuguquguquka kokugqibela kweemveliso zabo.

Ukusetyenziswa kwethu kwe-electroplating kunye nenkqubo iye yacokiswa ngaphezu kweminyaka engama-50.Asigxininisi kuphela ekuqinisekiseni eyona mveliso isemgangathweni kumthengi wethu, kodwa sikwazama konke okusemandleni ethu ukukhusela okusingqongileyo ukufezekisa uzinzo kwishishini lethu.

Kule nkonzo, sikwanoxanduva lomba wendalo esingqongileyo kwaye sithobela imfuneko ye-ROHS ngokusebenzisa imichiza enokuthanani nokusingqongileyo, eyimichiza.i-trivalent chromium plating (I-Trivalent Chromium)okanye (Cr3 +) kwinkqubo yethu.Iqela lethu lizibophelele ekunikeni abathengi bethu elona nqanaba liphezulu lenkxaso yobuchwephesha kunye nokuphumeza ukunciphisa imiphumo eyonakalisayo kokusingqongileyo.

Satin Chrome

I-Nikeli eqaqambileyo

Electroplating Door Trim nge Trivalent Chrome

I-Auto Door Knob

Izahlulo zemoto yePlastiki yeChrome

Kutheni Khetha Thina?

INkokeli yeHlabathi kwiiNkampani zePlastiki zeChrome! Ukukhetha iimveliso zethu kuthetha ukukhetha ngaphezu kwecandelo nje;ngumdibaniso ogqibeleleyo wokusungula, umgangatho, kunye nenkonzo egqwesileyo.Siqinisekile ukuba CheeYuen iplastiki electroplating umenzi liqabane kakhulu intsebenziswano ukuba ukhangela.

Ngaphezulu kweminyaka engama-54 yamava kwishishini leplastiki le-chrome plating

Sinenkqubo yokufakwa kwe-chrome ezenzekelayo

Sinenkqubo epheleleyo yokuvelisa

Umgangatho wemveliso uhambelana nemigangatho yamazwe ngamazwe

Ukwambathisa kumgca weplastiki Ubunakho

Idimenson yetanki yesisombululo kumgca wokucwenga ozenzekelayo yi-3000*1200*1500 MM.

Idimenson yetanki yesisombululo kumgca wokucwenga ojikelezayo yi-750*900*1500 MM.

Nge-1,500,000 yeemitha ze-Square ngonyaka kumthamo wokufakwa kweplastiki

Ubungqingqwa obuqhelekileyo beplating kwiindawo zokuhombisa iimoto:

Ubhedu 10-30 um

Nickel 5-15um

IChrome 0.1-0.3um

Amagqabantshintshi: Njengomthengi okanye inxalenye yerequrirement, sinokwenza uhlengahlengiso kwingcinga yokwaleka.

Izinto esinokuziqweba:

ABS

ABS/PC

PA6

PA66

Ukugqitywa kwe-Electroplating:

I-chrome eqaqambileyo

Satin chrome

I-chrome emnyama

Nickel yeSatin

I-Chrome w/ibrashi

Satin Nickel w/ibrashi

IChrome w/umzobo

Uvavanyo lomgangatho

Ukuqinisekisa umgangatho wemveliso kunye nokwandisa ukuzithemba kwabathengi, sinenkqubo yokuhlola esebenzisa ukuvavanya nokuhlalutya yonke inkqubo, kunye nokulawula umgangatho wezisombululo zekhemikhali kunye nezixhobo zokuvavanya umgangatho weemveliso

Abantu baphinde babuze:

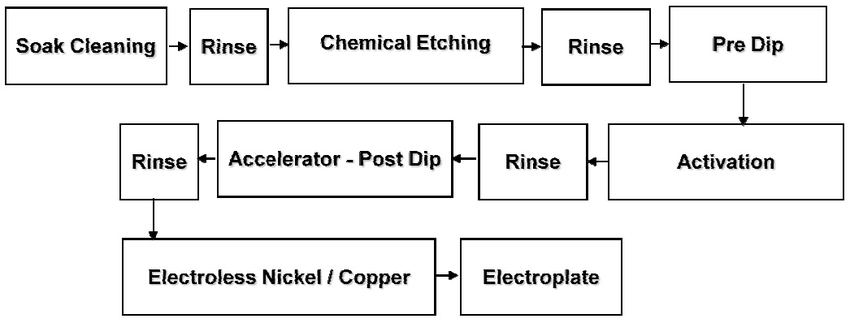

Ukucoca

Isusa igrisi, iminwe kunye nokungcola okunokuthi kuchaphazele kakubi ukuncamathelisa.

Ukulungiswa komphezulu

I-conditioner yomhlaba, elungiselelwe ukusuka kwi-asidi ekhethekileyo, iguqula i-

ubume bomphezulu weplastiki ngendlela yokuba ukunamathela okuqinileyo kunokufumaneka

phakathi kwayo kunye nekhemikhali yenikeli/ubhedu.Le meko linyathelo elibalulekileyo

unyango lweekhemikhali zeplastiki ukwenzela i-electroplating.Iziphene ezinxulumene nokubambelela kakubi zibangelwa ubukhulu becala bubume bomphezulu.

Ukusebenza komphezulu

I-activator yomhlaba iqulethe i-palladium, ethi inamathele kumphezulu we

iplastiki.Icandelo liye lintywiliselwe kwi-accelerator ukususa a

ifilimu ekhuselayo evela kumphezulu wepalladium.

Electroless nickel deposition

Icandelo elisebenzayo liza kuntywiliselwa kwisisombululo se-nickel engena-electro, leyo

idiphozithi umaleko obhityileyo wentsimbi phezu kwayo yonke substrate yeplastiki.Le ntsimbi

umaleko ke ube ngumqhubi we-electroplating elandelayo.

i-Electrolytic copper plating

Ukufakwa kwe-Electrolytic, i-nickel kunye ne-chrome

Ukomisa ngokufanelekileyo kwe-resin

I-ABS kufuneka yomiswe kwangaphambili kangangeeyure ezi-2–3 kwi-80–85 °C phambi kokubunjwa.

Izantya zokuzalisa ezifanelekileyo

Amacandelo amancinci ukuya kwi-90 g: 5-7 imizuzwana

Amacandelo amakhulu ngaphezu kwe-90 g: ukuya kuma-25 imizuzwana

Ubushushu obufanelekileyo bokunyibilika: 245–270 °C

Ubushushu bokunyibilika obubanda kakhulu bubangela uxinzelelo lwangaphakathi, olukhokelela kwi-etch engalinganiyo kunye nokusilela kovavanyo lokuhamba ngebhayisikile

Ubushushu obushushu kakhulu benyibilika bunokubangela ukuba imathiriyeli ithobeke kwaye inike ukuncamathela okulambathayo

Ubushushu obufanelekileyo bokungunda: 65–80 °C

Ukungunda okubanda kakhulu kuya kubangela ukuba iplastiki ivuthe.Izinto ezibetha udonga lokungunda ziba lukhuni kwaye izinto ezishushu phantsi kwazo ziyahamba, zenza isiphumo solusu esinokuthi sibangele i-delamination.

Ixesha lokupholisa elichanekileyo: ukuya kuthi ga kwimizuzwana engama-30

Amaxesha okupholisa amade anyusa umngcipheko woxinzelelo lwangaphakathi

Ukungunda okukhazimliswe kakhulu

Imiphezulu yokungunda engalunganga inokubangela iziphene kwindawo ebunjiweyo

Umxholo wokufuma kwezinto<0.02%

Yila amasango/imixokozelo yokuqukuqela ngaphandle koxinzelelo

Plateable ABS/PC

Ukukwazi ukwenza i-rack

Ukwanda kokuthandwa kokusetyenziswa kweeplastiki kunye neengxube zeplastiki kwiinkqubo ezininzi ezahlukeneyo zokwenziwa kwemveliso kukhokelela kwimfuno enkulu yokufakwa kweplastiki.Ukufakela iplastiki ngentsimbi yentsimbi kuphucula ukubonakala kwezinto kwaye kudala imbonakalo yomgangatho ophezulu.Ngenxa yoko, isoloko ikhethwa xa imbonakalo yokuhlobisa kakhulu ifunwa.

Ukongeza, ukufakwa kwiplastiki kunokuba yindlela esebenzayo yokukhusela i-substrate ngokuchasene nemikhosi yokubola kwaye iyenze ixhathise ngakumbi umonakalo ovela kwiikhemikhali ezisetyenziswa kwinkqubo yokuvelisa.Kwezinye iimeko, ukufakwa kwiplastiki kunokonyusa amandla kunye nokumelana nokunxiba kwe-substrate.

Njengoko sibonile kumzi mveliso weemoto, isibonelelo esibalulekileyo sokutyabeka kwiplastiki kukuba inokuphucula kakhulu inkangeleko ye-substrate.Uninzi lweeplastiki zemizi-mveliso zikholisa ukuba nesiphelo esibuthuntu.Ngelixa ukufaka umbala kwiplastiki kunokuyenza ibe nomtsalane ngakumbi, ayisayi kuvelisa inkangeleko eqaqambileyo, eqaqambileyo enqwenelwa ngabanini bemveliso abaninzi.Ngelixa ukucwenga nge-chrome kudala kuyindlela edumileyo kwizicelo zeemoto, iingozi zempilo ezinokubakho ezibangelwa yinkqubo yokucwenga yechromium enehexavalent ikhokelele ababoneleli abaninzi bokugqiba isinyithi ukuba baqeshe ezinye iindlela ezikhuselekileyo, ngakumbi i-nickel plating.

Ecaleni kwenkangeleko, ukufakwa kwiplastiki kunika ezinye izibonelelo ezininzi zeempawu zomzimba zento:

Ukonakala kunye nokumelana neekhemikhali: Ukufakwa kwiplastiki kunokuba yindlela esebenzayo yokukhusela i-substrate ngokuchasene nemikhosi yokubola kwaye iyenze ixhathise ngakumbi umonakalo ovela kwiikhemikhali ezisetyenziselwa inkqubo yokuvelisa.

Ukonyuka kokuqhuba: I-Electroplating inokunika umphezulu weplastiki ongeyo-conductive amandla okuqhuba umbane, ipropati exabiseke kakhulu kubenzi bamacandelo ombane kunye namalungu asetyenziswa kwiimoto, iinqwelomoya kunye nentaphane yezinye iimveliso.Ukugquma kwesinyithi kunokubonakalisa ukukhanya okunokonakalisa kude nomphezulu we-substrate yeplastiki kwaye isebenze njengomqobo okhuselayo kwiigesi ezinobungozi kunye nokuhlwa.Ukongezelela, i-metallization inokunceda ukulawula ukuchithwa kwamandla.

Ukonyuka kwamandla olwakhiwo:I-Electroplating inokuphucula amandla esakhiwo ngokubanzi ukwenzela ukuqina okukhulu.La mandla ongeziweyo yenye yeenzuzo eziphezulu ze-electroplating kwiplastiki.Ukuba amandla kuyinjongo yakho, i-nickel plating inokuba lukhetho oluhle kuba i-nickel inokuxhathisa ukubola kunye nokuphucula ubomi beemveliso.

Ukuxhathisa okuzinzileyo kunye nokuphantsi koqhagamshelwano:Ukongeza kwi-corrosion resistance, i-plating inokunciphisa ukunganyangeki koqhagamshelwano, ngoko unokonyusa ukuxhathisa kwenxalenye ukunxiba, iikhemikhali kunye nokubola.

Ukhuseleko lwe-RFI kunye ne-EMI: Izixhobo zombane zikhupha uphazamiseko lwe-electromagnetic (EMI) kunye nophazamiseko lwamaza kanomathotholo (RFI), olunegalelo kuphazamiseko lomqondiso kunye nokungasebenzi kakuhle kwezixhobo.I-Pating yongeza umaleko wokukhusela ukuvala la maza ayingozi e-EMI kunye ne-RFI.

Ukwambathisa kwiplastiki yindlela entle yokongeza ukuqina kuluhlu lweemeko ezahlukeneyo.Inika ukhuseleko lokugqoka kwansuku zonke ekunxibelelaneni, kunye nokukhusela okunamandla ngakumbi kwiikhemikhali kunye nokuphazamiseka.Okwangoku, ukuthembeka kwesakhiwo kuyinzuzo ebalulekileyo kwizicelo ezininzi, kwaye ukongeza i-conductivity kwiplastiki yindlela efanelekileyo yokwandisa ukuguquguquka koyilo lwenxalenye ngelixa ugcina indleko-esebenzayo yokwakhiwa kweplastiki.

Kukho iimeko ezahlukeneyo ngexesha lokubumba, ukuphatha, kunyeiplatingizinto zeplastiki ezinokukhokelela ekungafezeki kwemveliso egqityiweyo.Ukuqonda izizathu zokungafezeki okuqhelekileyo kunokuncedisa ekuchongeni izizathu ezisisiseko zezi ziphene kunye nokuphumeza ngokufanelekileyo izenzo zokulungisa kulo lonke ikhonkco lokubonelela.

Sdlala

I-Splay yiqela lekhefu, i-mars, okanye amanqaku, abonakala kwindawo echongiweyo.Nangona ibonakala kanye kuphela, ibangelwa imiba yam yokubumba;Ukufuma okubanjwe kwiplastiki kunokuza kumphezulu ngexesha lenkqubo ye-plating, kubangele i-splay.

Flash

Ifleshi yiplastiki ephuma kumda wenxalenye.I-Flash kwilungu elibunjiweyo lihlala lingaqatshelwa kude kube semva kokuba icandelo lichongiwe, kuba ukucwenga kuyakha kwiprotrusion.Olu qulunqo lweplate lunokwenza umphetho wenxalenye ubukhali, kwaye unokuphazamisana nokufaneleka kunye nokubonakala.Oku kungafezeki kubangelwa ngexesha lokubumba ngeplastiki engaphezulu okanye icandelo lingaphumi kubumba ngokucocekileyo.

Amadyungudyungu

I-blisters, njengemeko yesikhumba, iipokotho zomoya phantsi kwesikhumba-kulo mongo, phakathi kweplastiki kunye nediphozithi yensimbi.Njenge-splay, i-blisters inokubangelwa ngumswakama obanjwe ngaphakathi kwecandelo elibunjiweyo;nangona kunjalo, amadyungudyungu nawo anokubangelwa ngexesha lenkqubo yokucwenga, phakathi kweengqimba zediphozithi yesinyithi.Ukufumanisa imbangela ye-blister, yinqumle kwaye uhlambulule i-blister emva.Ukuba ivela kwiplastiki, kwaye i-underside ye-blister ineplastiki ehlulwe kwinxalenye, i-blister ibangelwa ukufuma okubanjwe ekubumbeni.

Imikrwelo kunye nezibonda

Imikrwelo kunye nezibonda zisenokubangelwa ngexesha lokubunjwa okanye ukuphatha (indawo ekrwada okanye ecandiweyo).Ngelixa ipleyiti iya kwenza uphicotho olungenayo kumacandelo abunjiweyo ukuze atyatyekwe, eminye imikrwelo okanye izibonda eplastikini zisenokungabonakali ngokukhawuleza, okanye iindawo ezikrwada zinokukrweleka ngexesha lokuphatha.Imikrwelo kunye nezibonda zinokuthi zenzeke ngexesha lokuphatha i-post-plate;inokwenzeka ukuba ixelelwe ngobunzulu bomkrwelo okanye isibotho kunye nediphozithi yokubekwa kwindawo ukuba ukungafezeki kungaphezulu okanye kwisiseko semathiriyeli.

Yoma Phantsi

Ukomisa phantsi konakele kwaye kwenzeka ngexesha lenkqubo yokucwenga xa inxalenye yome kakhulu phakathi kweediphozithi zetsimbi.Oku kunokuphetshwa ngolawulo olunyamekileyo lwenkqubo yokucwenga.

I-Wap

I-Warp yi-dimensional distortion yecandelo kwaye ingenzeka kwizigaba ezimbalwa zenkqubo yokuvelisa.Iimpazamo zokubumba zinokubangela i-warp, kwaye i-warp inokubangelwa kukuvezwa kwamaqondo obushushu agqithisileyo, ukukrazula indawo ngokungalunganga, okanye ukuyiphatha kakubi loo ndawo.

Tsiba ipleyiti

I-Skip plate kukungabikho kwe-plating ebusweni-izinto ezisisiseko zibonakaliswe.Inokubangelwa ukungcola phezu kwendawo, okuthintela ukufakwa kwi-plating phezu kwendawo.Ukuqinisekisa ukuba iindawo ezikrwada ziphathwa ngokufanelekileyo kwaye zigcinwe zingenazo izinto ezingcolisa umphezulu kunokunciphisa ukwenzeka kwe-skip plate.

I-Acrylonitrile-Butadiene-Styrene (ABS)

I-Acrylonitrile butadiene styrene (ABS) yipolymer ye-thermoplastic ethathwa ngokubanzi njengezinto zokuqala zeplastiki ezisetyenziselwa i-electroplating.Inkqubo yaphuhliswa ngokukodwa kwishishini leemoto kwiminyaka yoo-1960 kwaye isaqhutywa nanamhlanje.

Ewe - ungafumana iindawo zakho zeplastiki ziphathwe ngemibala efana ne-chrome (yentsimbi).Ukugqiba kwethu umbala kubandakanya i-electroplating, ngoko yomelele ngakumbi kwaye yomelele kunokugqiba ukutshiza kuphela.Ke ukuba ukhetha ideshibhodi yakho yeplastiki ukuba igqitywe ngombala kodwa ube unobunzulu kunye nokubengezela kokugqiba kwechrome-ungakwazi!

| Inkqubo | Inkcazo |

| Plastic Chroming Process/es for non metallic (kunye ne non ABS*) iinxalenye | Inkqubo yokwenza isinyithi kuqala.Emva koko i-'Triple Chrome' yagqitywa. Isibuko se-chrome ukugqiba. Ubhedu olomeleleyo, i-nickel, isakhiwo se-chrome |

| Inkqubo ye-ABS * iiplastiki | Inkqubo yolungiselelo lwenxalenye ekhethekileyo, emva koko i-'Triple Chrome' yafakwa.Isibuko se-chrome ukugqiba. Ubhedu olomeleleyo, i-nickel, isakhiwo se-chrome. |

| Ukugqunywa kweVacuum (Ukucoca isinyithi) | Ingubo "efana ne-chrome" (kungekhona i-chrome yokwenyani) ngetekhnoloji ye-vacuum. Ukugqiba okuqaqambileyo, okubhityileyo, okusiliva. Ukwaleka eludongeni olubhityileyo - lunokuthi lube nomonakalo.Inokwanela ezinye iinjongo. |

| Tshiza ichrome | Ipeyintiwe (esekelwe kwi-hybrid yepeyinti kunye nokugqitywa kweekhemikhali). Inokuba ngumdlalo osondeleyo kwi-chrome kodwa ithande ukwahluka ngenxa yomxube wombala kunye neendlela. Ukuqina kufana nepeyinti ye-2-pack. |

Inkqubo yePlastiki yeChrome

Inyathelo loku-1 - Ukucoca.Sintywilisela inxalenye kwitanki equlethe umxube we-sulfuric egxininisiweyo kunye ne-chromic acids.

Inyathelo lesi-2 - Ukungathathi hlangothi.

Inyathelo lesi-3 - Ukuhlaziya kunye nokuKhawuleza.

Inyathelo lesi-4 - Ukufakwa kwe-Electro-less.

Inyathelo lesi-5 - Ukufakwa kwe-Electro.

Inyathelo lesi-6 – Ukuhlolwa koMgangatho.

I-chrome yokwenyani, ngokuqinisekileyo unokupolisha kunye nesanti emanzi ukubuyisela ukugqiba.I-chrome ye-Fake (ifilimu yeplastiki okanye i-chrome plated) inokupholiswa, kodwa ngokukhawuleza kwefashoni.

Njengentsimbi,iplastiki nayo inokufakwa ngechrome.Ngale ndlela, kuya kufuneka uthumele iinxalenye zeplastiki ofuna ukuzongeza i-chrome ukuze uyifake.Iinkampani yokucocaiyakugquma indawo yakho kumaleko we-nickel kunye nobhedu ngaphambi kokuba isebenzise i-chrome.