Chrome Plating Plastic process

CheeYuen- Anotungamira mugadziri weElectroplating pamusoro pePlastiki Yakakupoteredza

Kuva aone-stop solution mupi, CheeYuen inozvikudza zvakasiyana-siyana zvehunyanzvi matarenda uye zvivakwa zvemazuva ano, zvichiita kuti tipe zvemhando yepamusoro, zvinogara chrome-plated finishes pazvikamu zvepurasitiki zvehukuru hwakasiyana uye maumbirwo.Zvichakadaro, isu tinokwanisa zvakare kupa vatengi neyakagadzirwa sevhisi, zvisinei nekuoma kana kukura kwechikamu.

Parizvino, tanga tichipa electroplating uye kupenda epurasitiki emotokari uye midziyo yekushongedza yemidziyo yemba yemhando dzinozivikanwa senge General motors, Ford, Fiat Chrysler, Volvo, Volkswagen, Tata, Mahindra, Toyota, Tesla, Delonghi, Grohe, American Standard, etc.

Kwemakore makumi mashanu nemana apfuura, takashandira vanopfuura makumi masere vane mukurumbira vemotokari nevatengi vemidziyo munyika makumi matatu nematunhu.

Isu takawana kurumbidzwa kwakanyanya uye kuzivikanwa nevatengi maererano nemutengo wedu wemakwikwi, kuita kwakasimba kwemhando, uye kuchinjika pamwe nekusvika nenguva.

Ndapota taura nesu nhasi kuti udzidze zvakawanda nezve yeduplastiki chrome plating sevhisi uye kuti tingakubatsira sei kuti uwane kupera kwakakwana kwezvikamu zvako zvepurasitiki.

Chrome Plating paPlastiki Zvikamu Sevhisi

CheeYuenine akawanda chrome mitsara ese pasi pedenga rimwe, achipa anochinjika sarudzo zvisinei kuti chikamu chei chinodiwa.Nesarudzo dzisingaperi dzemavara, mashandisirwo echinyakare, maumbirwo uye inoenderera mberi magadzirirwo ekuita, tiri kuenderera mberi nekuwedzera kugona kwedu uye nekupa vatengi vedu iyo yekupedzisira shanduko yezvigadzirwa zvavo.

Yedu electroplating application uye maitiro akakwenenzverwa kweanopfuura makore makumi mashanu.Isu hatisi kungosimbisa chete pakuratidza yakanakisa mhando chigadzirwa kumutengi wedu, asi isu tinoedzawo zvatinogona kuchengetedza nharaunda kuti tiwane kusimudzira mubhizinesi redu.

Kune iyi sevhisi, isu zvakare tine basa rezvakatipoteredza nyaya uye tinoenderana neROHS zvinodiwa nekushandisa makemikari zvinhu zviri zvakatipoteredza zvisingaite, izvo zviritrivalent chromium plating (Trivalent Chromium)kana (Cr3+) mukuita kwedu.Chikwata chedu chakazvipira kupa vatengi vedu chikamu chepamusoro cherutsigiro rwehunyanzvi uye kubudirira kuderedza zvinokuvadza zvakatipoteredza.

Satin Chrome

Bright Nickel

Electroplating Door Trim ine Trivalent Chrome

Auto Door Knob

Chrome Plating Yemotokari Zvikamu

Sei Tisarudze?

Mutungamiri Wepasi Pose muPlastiki Chrome Plating Companies!Kusarudza zvigadzirwa zvedu zvinoreva kusarudza zvinopfuura chikamu;musanganiswa wakakwana wekuvandudza, mhando, uye sevhisi yakanaka.Isu tine chokwadi chekuti CheeYuen epurasitiki electroplating mugadziri ndiye anonyatso shandira pamwe wauri kutsvaga.

Neanopfuura makore makumi mashanu nemana echiitiko muindasitiri yepurasitiki chrome plating

Tine otomatiki chrome plating process

Tine chirongwa chakakwana chekugadzira

Hunhu hwechigadzirwa hunoenderana nezviyero zvepasi rose

Kupfekedza pamutsetse wepurasitiki Kugona

Iyo mhinduro tangi dimenson ye otomatiki plating mutsara ndeye 3000 * 1200 * 1500 MM.

Iyo mhinduro tank dimenson yedenderedzwa plating mutsara ndeye 750 * 900 * 1500 MM.

Iine 1,500,000 Square metres pagore pane epurasitiki plating kugona

Yakajairika plating ukobvu kune mota dzekushongedza zvikamu:

Mhangura 10-30 um

Nickel 5-15um

Chrome 0.1-0.3um

Matauriro: Sezvemutengi kana chikamu chinodiwa, isu tinogona kugadzirisa pakufunga kufunga.

Zvinhu zvatingagona kurongedza:

ABS

ABS/PC

PA6

PA66

Electroplating inopera:

Chrome inopenya

Satin chrome

Black chrome

Satin nickel

Chrome w/brushing

Satin Nickel w/brashing

Chrome w/engraving

Quality Testing

Kuve nechokwadi chemhando yechigadzirwa uye kuwedzera chivimbo chevatengi, isu tine yekuongorora system inoshandisa kuyedza uye kuongorora maitiro ese, uye kudzora kunaka kwemakemikari mhinduro ne chemistry uye zviridzwa zvekuyedza kunaka kwezvigadzirwa ne.

Vanhu Vanobvunzawo:

Kuchenesa

Inobvisa girisi, mafingerprints uye tsvina izvo zvingangokanganisa kunamatira.

Kugadzirira kwepamusoro

Iyo yepamusoro conditioner, iyo inogadzirwa kubva kune yakakosha asidhi, inoshandura iyo

chimiro chepamusoro pepurasitiki nenzira yekuti kunamatira kwakasimba kunogona kuwanikwa

pakati payo nekemikari nickel/copper.Iyi conditioning inhanho yakakosha mukati

kurapwa kwemakemikari epurasitiki ye electroplating.Zvikanganiso zvine chekuita nekusanamatira zvakanaka zvinonyanya kukonzerwa nekugadziriswa kwepamusoro.

Surface activation

Iyo yepamusoro activator ine palladium, inozvisungirira pachayo pamusoro pe

plastiki.Chikamu chinobva chanyudzwa mune accelerator kubvisa a

firimu rinodzivirira kubva pamusoro pepalladium.

Electroless nickel deposition

The activated component inobva yanyudzwa mune electroless nickel solution, iyo

inoisa chidimbu chesimbi pamusoro pepasi rose repurasitiki.Simbi iyi

layer inobva yava conductor yeinotevera electroplating.

Electrolytic copper plating

Electrolytic plating, nickel uye chrome

Kuomeswa kwakakodzera kweresin

ABS inofanira kunge isati yaomeswa kwemaawa 2–3 pa80–85 °C isati yaumbwa.

Zvakakodzera kuzadza kumhanya

Zvikamu zviduku kusvika ku90 g: 5-7 secs

Zvikamu zvakakura kupfuura 90 g: kusvika ku25 secs

Tembiricha yekunyungudika yakakodzera: 245–270 °C

Kunyanya-kutonhora kunyunguduka tembiricha kunokonzeresa kushushikana kwemukati, zvichitungamira kune kusaenzana etch uye yekupisa bhasikoro bvunzo kutadza

Kunyanya-kupisa kunyunguduka tembiricha kunogona kukonzera kuti zvinhu zvidzikire uye zvipe kusanamatira zvakanaka

Kupisa kwakakodzera kweforoma: 65–80 °C

Kunyanya kutonhora mold ichaita kuti plastiki iite.Zvinhu zvinorova madziro eforoma zvinoomesa uye zvinhu zvinopisa zviri pasi pazvo zvinoyerera, zvichigadzira ganda repamusoro rinogona kukonzera delamination.

Nguva yekutonhora yakakodzera: kusvika ku30 secs

Nguva refu yekutonhora inowedzera njodzi yekushushikana kwemukati

Yakanyanya kukwenenzverwa mold

Nzvimbo dzisina kunaka dze mold dzinogona kukonzera kukanganisa muchikamu chakaumbwa

Material mwando<0.02%

Gadzira magedhi / mu-mu-mold kuitira tension yemahara-mould kuyerera

Plateable ABS/PC

Kugona rack

Kuwedzera kukurumbira kwekushandiswa kwemapurasitiki nemapurasitiki anoumba mumhando dzakasiyana siyana dzekugadzira kwakonzerawo kudiwa kukuru kwekuputira papurasitiki.Kupfekedza mapurasitiki nesimbi yepamusoro kunowedzera kutaridzika kwezvinhu uye kunogadzira fungidziro yemhando yepamusoro.Somugumisiro, inowanzosarudzwa kana kutaridzika kwakanyanya kwekushongedza kunodiwa.

Pamusoro pezvo, kupfekedza papurasitiki kunogona kuve nzira inoshanda yekudzivirira substrate kubva kune masimba ekuora uye kuita kuti isarambe kukuvara kubva kumakemikari anoshandiswa mukugadzira.Mune zvimwe zviitiko, kuputira papurasitiki kunogona kuwedzera simba uye kupfeka kuramba kweiyo substrate.

Sezvataona muindasitiri yemotokari, bhenefiti yakakosha yekuputira papurasitiki ndeyekuti inogona kuwedzera zvakanyanya kutaridzika kweiyo substrate.Mazhinji mapurasitiki eindasitiri anowanzo kuve nekupera kwakashata.Nepo kupendesa purasitiki kunogona kuita kuti iwedzere kutaridzika, haisati ichizoburitsa kupenya, kupenya kutaridzika kunodiwa nevaridzi vezvigadzirwa.Kunyange kuputira nechrome kwagara kuri nzira yakakurumbira mukushandisa mota, njodzi dzinogona kuitika pahutano dzinounzwa nehexavalent chromium plating process yatungamira vazhinji vanopa simbi yekupedzisa kushandisa dzimwe nzira dzakachengeteka, kunyanya nickel plating.

Padivi pechitarisiko, kuputira papurasitiki kunopa zvimwe zvakati wandei mabhenefiti echimiro chechinhu chacho:

Corrosion uye makemikari kuramba: Kupfekedza pamapurasitiki kunogona kuva nzira inoshanda yekudzivirira substrate kubva kune masimba ekuora uye kuita kuti iwedzere kupikisa kukuvara kubva kumakemikari anoshandiswa mukugadzira.

Kuwedzera conductivity: Electroplating inogonawo kupa iyo isiri-conductive yepurasitiki pasi kugona kuitisa magetsi, chivako chakakosha kune vanogadzira zvemagetsi zvikamu uye zvikamu zvinoshandiswa mumotokari, ndege uye akawanda ezvimwe zvigadzirwa.Simbi yekuputira inogona zvakare kuratidza inogona kukuvadza mwenje kure nepamusoro pepurasitiki substrate uye inoshanda sechidziviriro chekudzivirira kubva kune inokuvadza magasi uye ngura.Uyezve, metallization inogona kubatsira kudzora kupera kwesimba.

Kuwedzera simba rechimiro:Electroplating inogona kuvandudza simba rechimiro chechikamu chekusimba kukuru.Iri rakawedzerwa simba nderimwe repamusoro mabhenefiti e electroplating papurasitiki.Kana simba riri iro chinangwa chako, nickel plating inogona kuve sarudzo yakanaka sezvo nickel inogona kuramba corrosion uye kugadzirisa hupenyu hwezvigadzirwa.

Yakagadzikana uye yakaderera kuonana kuramba:Pamusoro pekupokana necorrosion, plating inogona zvakare kuderedza kubata kuramba, saka iwe unogona kuwedzera chikamu chekudzivirira kupfeka, makemikari uye ngura.

RFI uye EMI kudzivirira: Zvishandiso zvemagetsi zvinoburitsa electromagnetic interference (EMI) uye redhiyo frequency interference (RFI), izvo zvinokonzeresa kukanganisa kwemasaini uye kusashanda zvakanaka kwemidziyo.Plating inowedzera chidziviriro kudzivirira aya anokuvadza EMI uye RFI mafungu.

Kurovera papurasitiki inzira huru yekuwedzera kusimba munzvimbo dzakasiyana siyana.Inopa dziviriro yekupfeka kwemazuva ese kubva pakubata, pamwe nekuwedzera kwakasimba kudzivirira kubva kumakemikari uye kupindira.Zvichakadaro, kutendeseka kwechimiro chinhu chakakosha mukushandisa kwakawanda, uye kuwedzera conductivity kupurasitiki inzira huru yekuwedzera dhizaini kuchinjika kwechikamu uchichengetedza iyo inodhura-inoshanda hunhu hwekuvakwa kwepurasitiki.

Pane mamiriro akasiyana-siyana panguva yekuumbwa, kubata, uyeplatingyezvikamu zvepurasitiki izvo zvinogona kutungamira mukusakwana muchigadzirwa chakapedzwa.Kunzwisisa zvinokonzeresa kumwe kusakwana kwakajairwa kunogona kubatsira mukuona zvikonzero zvekusakwana uku uye kuita zvinobudirira zviito zvekugadzirisa panguva yese yekugovera.

Splay

Splay isumbu remabreak, mars, kana mamaki, anoonekwa pane akapfava chikamu.Kunyangwe ichingoonekwa kamwe chete yaputirwa, ikonzeresa nyaya dzangu dzekuumba;yakavharirwa mwando mupurasitiki inogona kuuya pamusoro panguva yekugadzira, zvichikonzera splay.

Flash

Kupenya kuburitswa kwepurasitiki pachikamu chemupendero.Kupenya pachinhu chakaumbwa kazhinji hachionekwe kusvika mushure mekunge chikamu chaputirwa, nekuti plating inovaka pamusoro peiyo protrusion.Iri ndiro rinovaka ndiro rinogona kuita kuti mupendero wechikamu unopinza, uye unogonawo kukanganisa kukodzera uye kuonekwa.Kusakwana uku kunokonzerwa panguva yekuumbwa nepurasitiki yakawandisa kana chikamu chisina kutyora kubva mukuumbwa zvakachena.

Matuzu

Mablister, semamiriro eganda, ihomwe dzemhepo pasi peganda-mune mamiriro ezvinhu aya, pakati pepurasitiki nesimbi deposit.Sezvakaita splay, blisters inogona kukonzerwa nehunyoro hwakavharirwa mukati mechikamu chakaumbwa;zvisinei, blisters inogonawo kukonzerwa panguva yekuputira, pakati pezvikamu zvesimbi dhipoziti.Kuti uone chikonzero che blister, cheka uye bvisa blister kumashure.Kana ichibva papurasitiki, uye pasi pe blister ine plastiki yakaparadzana kubva kune chikamu, blister yakakonzerwa nekuvharirwa hunyoro mukuumba.

Makwara uye Dents

Kukwenya uye dents zvinogona kukonzerwa panguva yekuumbwa kana kubata (yeiyo mbishi kana yakapfava chikamu).Nepo plater ichiwanzoita ongororo iri kuuya pazvinhu zvakaumbwa zvekuputira, mamwe mavanga kana dents mupurasitiki anogona kunge asiri kuoneka nekukasika, kana zvidimbu mbishi zvinogona kukweshwa panguva yekubata.Kukwenya uye dents zvinogonawo kuitika panguva yekubata post-plate;zvinogoneka kutaurwa nekudzika kwekukwenya kana dhipoziti uye plating dhipoziti panzvimbo yacho kuti kusakwana kuri kwepamusoro kana muhwaro hwezvinhu.

Dry Down

Dry down is marred plating uye inoitika panguva yeplating process apo chikamu chinenge chanyanya kuoma pakati pesimbi deposits.Izvi zvinogona kudzivirirwa nekuchenjerera maitiro ekutonga kweplating oparesheni.

Warp

Warp ndiyo dimensional kukanganisa kwechikamu uye inogona kuitika pamatanho mashoma ekugadzira maitiro.Kukanganisa kwekuumba kunogona kukonzera warp, uye warp inogonawo kukonzerwa nekuratidzwa kune tembiricha yakanyanyisa, kukwenya chikamu zvisizvo, kana kubata chikamu zvisina kunaka.

Skip ndiro

Skip plate ndiko kusavapo kweplating pamusoro-iyo base zvinhu zvinoburitswa pachena.Inogona kukonzerwa nekusvibiswa kwepamusoro pechikamu, izvo zvinodzivirira kuvhara kubva pakuiswa pamusoro pechikamu.Kuve nechokwadi chekuti mativi mbishi anobatwa nemazvo uye akachengetedzwa asina tsvina yepasi anogona kuderedza kuitika kweskip plate.

Acrylonitrile-Butadiene-Styrene (ABS)

Acrylonitrile butadiene styrene (ABS) inonzi thermoplastic polymer inowanzoonekwa seyekutanga epurasitiki zvinhu zvinoshandiswa pa electroplating.Maitiro acho akagadzirirwa chaizvo indasitiri yemotokari muma1960 uye ichiri kuitwa nhasi.

Hongu - iwe unogona kuwana ako epurasitiki zvikamu zvakarapwa mune chrome-senge (simbi) mavara.Kupedzisa kwemavara edu kunosanganisira electroplating, saka inogara yakasimba uye yakasimba pane kupfapfaidza kupera chete.Saka kana ukada dhibhodhi rako repurasitiki kuti ripedzwe muruvara asi uchine hudzamu uye kupenya kwekupedzisa kwechrome - unogona!

| Process | Tsanangudzo |

| Plastiki Chroming Maitiro/es kune asiri esimbi (uye asiri ABS*) zvikamu | Metallising process kutanga.Ipapo 'Triple Chrome' yakapetwa. Mirror chrome kupera. Yakasimba mhangura, nickel, chrome chimiro |

| Maitiro eABS * mapurasitiki | Yakakosha chikamu chekugadzirira maitiro, ipapo 'Triple Chrome' yakapetwa.Mirror chrome kupera. Yakasimba mhangura, nickel, chrome chimiro. |

| Vacuum Coating (Vacuum Metallising) | Iyo "chrome-yakafanana" yekuvhara (kwete chaiyo chrome) kuburikidza ne vacuum tekinoroji. Yakapenya, yakaonda, sirivheri kupera. Mushonga wakaonda wemadziro - anogona kuve anowanzo kukuvara.Inogona kunge yakakwana kune zvimwe zvinangwa. |

| Mwaya chrome | Painted (yakavakirwa pane yakasanganiswa pendi & kupedzisa kemikari). Inogona kunge iri padyo match kune chrome asi yakajairwa kusiyanisa nekuda kwekusanganiswa kwemavara uye nzira. Kugara kwakafanana ne 2-pack pendi. |

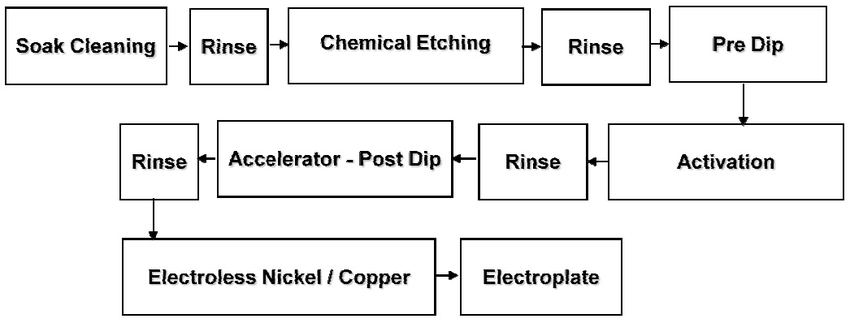

Chrome Plastic Plating process

Danho 1 - Kushongedza.Isu tinonyudza chikamu mutangi ine musanganiswa we concentrated sulfuric uye chromic acids.

Danho 2 - Neutralization.

Nhanho 3 - Kugadzirisa uye Kuwedzera.

Nhanho 4 - Electro-less Plating.

Nhanho 5 - Electro Plating.

Nhanho 6 - Kuongorora Kwemhando.

Chaiyo chrome, iwe zvechokwadi unogona kupukuta uye kunyorova jecha kudzoreredza kupera.Fake chrome (yepurasitiki firimu kana chrome yakaiswa mukati) inogona kukwenenzverwa, asi mune yakareruka yefashoni.

Sesimbi,plastiki inogona zvakare kuve chrome yakaputirwa.Kune iyi nzira, iwe uchafanirwa kutumira zvikamu zvepurasitiki zvaunoda kuwedzera chrome kune yekuputira.Theplating kambaniichapfekedza chikamu chako muzvikamu zve nickel nemhangura isati yaisa chrome.