Chrome Plating Tsari

CheeYuen- Jagoran masana'anta na Electroplating akan Filastik A kusa da ku

Kasancewa amai bada mafita ta tasha daya, CheeYuen yana ba da ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun chrome, waɗanda ke ba mu damar samar da inganci mai inganci, ɗorewa na chrome-plated akan abubuwan filastik daban-daban masu girma dabam da siffofi.A halin yanzu, muna kuma iya ba abokan ciniki sabis ɗin ɗinkin da aka ƙera, ba tare da la'akari da rikitarwa ko girman sashin ba.

A halin yanzu, muna da aka samar da electroplating da zanen roba mota da kuma gida kayan ado na kayan ado aka gyara ga sanannun brands kamar General Motors, Ford, Fiat Chrysler, Volvo, Volkswagen, Tata, Mahindra, Toyota, Tesla, Delonghi, Grohe, American Standard, da dai sauransu.

A cikin shekaru 54 da suka gabata, mun yi hidima fiye da 80 shahararrun motoci da abokan cinikin kayan aiki a cikin ƙasashe da yankuna daban-daban na 30.

Abokan ciniki sun sami babban yabo da karramawa dangane da farashi mai fa'ida, ingantaccen aiki mai inganci, da sassauƙa da isarwa akan lokaci.

Da fatan za a tuntuɓe mu a yau don ƙarin koyo game da namufilastik chrome plating sabis da kuma yadda za mu iya taimaka muku cimma cikakkiyar ƙare don abubuwan haɗin filastik ku.

Chrome Plating akan Sabis na Sassan Filastik

CheeYinyana da layukan chrome da yawa duk ƙarƙashin rufin ɗaya, yana ba da zaɓuɓɓuka masu sassauƙa komai girman girman ɓangaren da ake buƙata.Tare da zaɓuɓɓukan launi marasa iyaka, aikace-aikacen al'ada, laushi da ci gaba mai dorewa, muna ci gaba da fadada iyawarmu da samar da abokan cinikinmu tare da sassaucin ra'ayi na samfurori.

Our electroplating aikace-aikace da kuma tsari da aka mai ladabi fiye da shekaru 50.Ba wai kawai muna ƙarfafawa akan tabbatar da mafi kyawun samfurin ga abokin cinikinmu ba, amma muna kuma ƙoƙarinmu don kare muhalli don samun dorewa a cikin kasuwancinmu.

Don wannan sabis ɗin, mu ma muna da alhakin batun muhalli kuma muna biyan buƙatun ROHS ta amfani da abubuwan sinadarai waɗanda ke da ƙarancin muhalli, waɗanda suketrivalent chromium plating (Trivalent Chromium)ko (Cr3+) a cikin tsarin mu.Ƙungiyarmu ta himmatu don ba abokan cinikinmu mafi girman matakin tallafin ƙwararru da cimma nasarar rage illa ga muhalli.

Satin Chrome

Nickel mai haske

Gyaran Ƙofar Electroplating tare da Chrome Trivalent

Ƙofar Kofa ta atomatik

Rumbun Rubutun Mota na Chrome

Me yasa Zabe Mu?

Jagoran Duniya a Kamfanonin Plastic Plastic Chrome Plating!Zaɓin samfuranmu yana nufin zabar fiye da kawai sashi;cikakkiyar haɗakar ƙira ce, inganci, da kyakkyawan sabis.Mun gamsu cewa CheeYuen filastik mai yin lantarki shine abokin haɗin gwiwa wanda kuke nema.

Tare da fiye da shekaru 54 na gwaninta a cikin masana'antar filastik chrome plating

Muna da tsari na chrome plating ta atomatik

Muna da cikakken tsari na samarwa

Ingancin samfurin ya dace da ƙa'idodin ƙasashen duniya

Sanya Layukan Filastik

Maganin tanki dimenson don layin plating ta atomatik shine 3000*1200*1500mm

Maganin tanki dimenson don layin plating madauwari shine 750 * 900 * 1500 mm

Tare da murabba'in murabba'in mita 1,500,000 a kowace shekara akan ƙarfin platin filastik

Yawan kauri na plating don sassa na kayan ado na mota:

Copper 10-30 um

Nickel 5-15 um

Chrome 0.1-0.3um

Bayani: Dangane da buƙatun abokin ciniki ko sashi, za mu iya yin gyare-gyare kan tunanin shafi.

Abubuwan da za mu iya farantawa:

ABS

PC/ABS

PA6

PA66

Electroplating ya ƙare:

chrome mai haske

Satin chrome

Black chrome

Satin nickel

Chrome tare da gogewa

Satin Nickel tare da goge baki

Chrome tare da zane-zane

Gwajin inganci

Don tabbatar da ingancin samfurin da haɓaka amincewar abokin ciniki, muna da tsarin dubawa wanda ke amfani da shi don gwadawa da bincika kowane tsari, kuma don sarrafa ingancin samfuran sinadarai tare da sinadarai da kayan aiki don gwada ingancin samfuran ta

An kuma tambayi mutane:

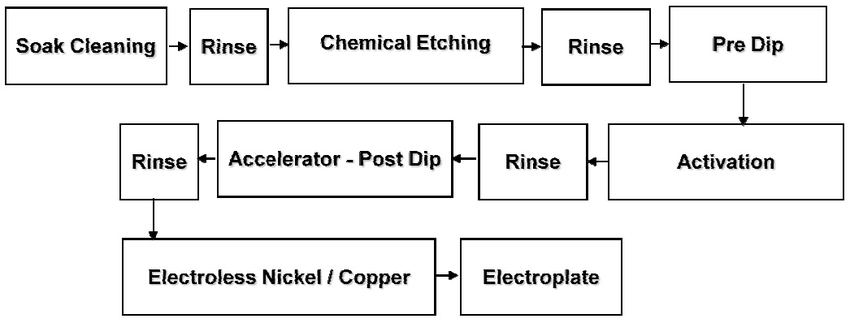

Tsaftacewa

Yana kawar da maiko, sawun yatsa da ƙazanta waɗanda in ba haka ba za su yi illa ga mannewa.

Shirye-shiryen saman

Na'urar kwandishan, wanda aka shirya daga acid na musamman, yana canza yanayin

tsarin filayen filastik ta yadda za a iya samun mannewa mai karfi

tsakaninsa da sinadarin nickel/Copper.Wannan kwandishan wani muhimmin mataki ne a ciki

da sinadaran magani na filastik don electroplating.Lalacewar da ke da alaƙa da ƙarancin mannewa yawanci ana haifar da su ta yanayin yanayin ƙasa.

Kunna saman

The surface activator ya ƙunshi palladium, wanda attaches kanta zuwa saman na

filastik.Sannan ana nutsar da bangaren a cikin abin totur don cire a

fim ɗin kariya daga saman palladium.

Zubar da nickel mara amfani

Sa'an nan an kunna bangaren da aka kunna a cikin ruwan nickel maras amfani, wanda

yana ajiye wani ɗan ƙaramin ƙarfe na bakin ciki a kan gabaɗayan ƙwayar filastik.Wannan karfe

Layer sa'an nan ya zama madugu na gaba electroplating.

Electrolytic jan karfe plating

Electrolytic plating, nickel da chrome

Daidaitaccen bushewar guduro

Dole ne a bushe ABS na sa'o'i 2-3 a 80-85 ° C kafin yin gyare-gyare.

Gudun cika daidai

Ƙananan sassa har zuwa 90 g: 5-7 seconds

Manyan abubuwa sama da 90 g: har zuwa 25 seconds

Narkewar zafin jiki mai kyau: 245-270 ° C

Yawan narkewar sanyi mai yawa yana haifar da damuwa na ciki, yana haifar da rashin daidaituwar etch da gazawar gwajin hawan keke

Zazzabi mai zafi mai zafi na iya haifar da kayan ya lalace kuma ya ba da mannewa mara kyau

Madaidaicin zafin jiki: 65-80 ° C

Tushen sanyi da yawa zai sa robobin ya fashe.Abubuwan da ke bugun bangon ƙira suna taurare kuma kayan zafi suna gudana a ƙarƙashinsa, suna haifar da tasirin fata wanda zai iya haifar da lalata.

Lokacin sanyaya daidai: har zuwa 30 seconds

Tsawon lokacin sanyi yana ƙara haɗarin damuwa na ciki

Sosai goge mold

Wuraren ƙera mara kyau na iya haifar da lahani a ɓangaren da aka ƙera

Abun ciki danshi<0.02%

Zane kofofin / in-moulds don tashin hankali free-mould kwarara

ABS / PC mai ɗaukar hoto

Yiwuwar tarawa

Karuwar shaharar amfani da robobi da hada-hadar robobi a fannonin masana'antu iri-iri ya kuma haifar da bukatuwa da yawa don sanyawa filastik.Sanya filastik tare da saman karfe yana haɓaka bayyanar kayan kuma yana haifar da ra'ayi mafi girma.A sakamakon haka, ana zaɓar sau da yawa lokacin da ake son kyan gani na ado sosai.

Bugu da ƙari, sanya a kan robobi na iya zama ingantacciyar hanyar kare ƙasa daga ƙarfin lalata da kuma sanya shi mafi juriya ga lalacewa daga sinadarai da ake amfani da su a cikin tsarin masana'antu.A wasu lokuta, sanyawa a kan robobi na iya ƙara ƙarfi da juriya na ma'aunin.

Kamar yadda muka gani a cikin masana'antar kera motoci, muhimmin fa'ida na sanyawa a kan filastik shi ne cewa yana iya haɓaka kamannin ƙirar.Yawancin robobi na masana'antu suna da ƙarancin ƙarewa.Duk da yake canza launin filastik na iya sa shi ya zama abin sha'awa na gani, har yanzu ba zai haifar da haske mai haske ba wanda yawancin masu samfurin ke so.Yayinda plating tare da chrome ya kasance sanannen fasaha a cikin aikace-aikacen mota, yuwuwar haɗarin kiwon lafiya da ke haifar da tsari na chromium plating na hexavalent ya haifar da yawancin masu samar da ƙarfe don yin amfani da mafi aminci madadin, musamman plating nickel.

Tare da bayyanar, sanyawa kan filastik yana ba da fa'idodi da yawa don halayen zahirin abun:

Lalata da juriya na sinadarai: Sanya a kan filastik na iya zama ingantacciyar hanyar kare ƙasa daga ƙarfin lalata da kuma sanya shi mafi juriya ga lalacewa daga sinadarai da ake amfani da su a cikin tsarin masana'antu.

Ƙara yawan aiki: Electroplating kuma yana iya ba filin filastik da ba ya aiki da ikon sarrafa wutar lantarki, dukiya da ke da kima ga masu kera sassa na lantarki da abubuwan da ake amfani da su a cikin motoci, jiragen sama da ɗimbin kayayyaki.Har ila yau, murfin ƙarfe na iya nuna haske mai yuwuwar yin lahani daga saman ɗigon filastik kuma ya zama shinge mai kariya daga iskar gas mai cutarwa da lalata.Bugu da ƙari, ƙarfe na iya taimakawa wajen sarrafa ɓarnar makamashi.

Ƙarfafa ƙarfin tsari:Electroplating na iya inganta ƙarfin tsarin sashe gaba ɗaya don ƙarin karko.Wannan ƙarin ƙarfin yana ɗaya daga cikin manyan fa'idodin na'urar lantarki akan filastik.Idan ƙarfi shine burin ku, nickel plating na iya zama kyakkyawan zaɓi tunda nickel na iya tsayayya da lalata da haɓaka rayuwar samfuran.

Tsaya da ƙarancin juriya:Baya ga juriya na lalata, plating kuma na iya rage juriyar lamba, don haka za ku iya ƙara juriyar sashe, sinadarai da lalata.

Kariyar RFI da EMI: Na'urorin lantarki suna sakin tsangwama na lantarki (EMI) da tsangwama na mitar rediyo (RFI), waɗanda ke ba da gudummawa ga katsewar sigina da rashin aiki na kayan aiki.Plating yana ƙara matakan kariya don toshe waɗannan raƙuman ruwa na EMI da RFI masu cutarwa.

Sanya robobi babbar hanya ce don ƙara dawwama a cikin kewayon wurare daban-daban.Yana ba da kariya ga lalacewa ta yau da kullun daga tuntuɓar juna, da kuma ƙarin kariya mai ƙarfi daga sinadarai da tsangwama.A halin yanzu, daidaiton tsari yana da fa'ida mai mahimmanci a cikin aikace-aikacen da yawa, kuma ƙara haɓakawa zuwa filastik hanya ce mai kyau don haɓaka ƙirar ƙira ta wani ɓangaren yayin da ake kiyaye yanayin tsadar kayan gini na filastik.

Akwai yanayi iri-iri a lokacin gyare-gyare, kulawa, daplatingna kayan aikin filastik waɗanda zasu iya haifar da rashin ƙarfi a cikin ƙãre samfurin.Fahimtar abubuwan da ke haifar da wasu nakasassun gama gari na iya taimakawa wajen gano tushen waɗannan kurakuran da aiwatar da ingantattun ayyukan gyara a cikin sarkar samarwa.

Splay

Splay gungu ne na karyewa, mars, ko alamomi, wanda ake iya gani akan wani sashe.Ko da yake ana iya ganin shi sau ɗaya an rufe shi, yana haifar da matsalolin gyare-gyare na;danshi mai tarko a cikin robobi na iya zuwa sama yayin da ake yin platining, yana haifar da splay.

Filasha

Filashin filasha ne na filastik a gefen ɓangaren.Filanci akan abin da aka ƙera sau da yawa ba a lura da shi ba har sai bayan an yi plate ɗin abin, saboda platin yana haɓaka kan fitowar.Wannan ginin farantin yana iya sa gefen sashin ya kaifi, kuma yana iya tsoma baki tare da dacewa da bayyanar.Ana haifar da wannan ajizanci yayin gyare-gyare ta hanyar filastik da yawa ko kuma ɓangaren da ba ya karye daga tsaftar.

Kumburi

Blisters, kamar yanayin fata, aljihun iska ne a ƙarƙashin fata-a cikin wannan mahallin, tsakanin filastik da ajiyar ƙarfe.Kamar splay, blisters na iya haifar da damshin da ya kama a cikin abin da aka ƙera;duk da haka, ana iya haifar da blisters yayin aikin plating, tsakanin yadudduka na ajiyar ƙarfe.Domin sanin dalilin kumburin ciki, yanke da bawo blister a baya.Idan ya samo asali daga filastik, kuma gefen blister yana da filastik wanda ya rabu da abin da ke ciki, blister yana fitowa daga danshi a cikin gyare-gyare.

Scratches da Dents

Za a iya haifar da ƙulle-ƙulle da haƙarƙari yayin gyare-gyare ko kulawa (na ɓangaren danye ko plated).Yayin da farantin za ta gudanar da bincike mai shigowa akan abubuwan da aka ƙera don yin gyare-gyare, wasu tarkace ko ɓarna a cikin filastik ba za su iya fitowa nan da nan ba, ko kuma za a iya toshe ɗanyen sassa yayin sarrafawa.Scratches da hakora kuma na iya faruwa a lokacin sarrafa bayan farantin;yana iya yiwuwa a iya faɗi ta zurfin karce ko ɓarna da saka ajiya akan wurin ko ajizancin na sama ne ko a cikin kayan tushe.

Dry Down

Dry down ya lalace kuma yana faruwa a lokacin aikin platining lokacin da sashin ya bushe sosai tsakanin ajiyar ƙarfe.Ana iya kauce wa wannan ta hanyar kulawa da tsari mai kyau na aikin plating.

Warp

Warp shine murguda juzu'i na sashi kuma yana iya faruwa a ƴan matakai na aikin samarwa.Kurakurai na gyare-gyare na iya haifar da yaƙe-yaƙe, kuma zazzaɓi kuma na iya haifar da faɗuwa zuwa matsanancin yanayin zafi, tara sashin ba daidai ba, ko karkatar da sashin.

Tsallake farantin

Tsallake farantin shine rashin plating akan saman - kayan tushe yana fallasa.Ana iya haifar da shi ta hanyar gurɓataccen abu a saman sashin, wanda ke hana sanya platin a saman sashin.Tabbatar da cewa an sarrafa ɗanyen sassa yadda ya kamata kuma a kiyaye su daga gurɓatar ƙasa na iya rage faruwar farantin tsalle.

Acrylonitrile-Butadiene-Styrene (ABS)

Acrylonitrile butadiene styrene (ABS) polymer ne na thermoplastic wanda aka fi sani da shi azaman kayan filastik na farko da aka yi amfani da shi don lantarki.An haɓaka tsarin musamman don masana'antar kera motoci a cikin 1960s kuma har yanzu ana aiwatar da shi a yau.

Ee - za ku iya samun nau'ikan filastik ɗinku da aka yi musu magani da launuka masu kama da chrome (ƙarfe).Ƙarshen launi ɗin mu ya haɗa da electroplating, don haka ya fi ɗorewa da ƙarfi fiye da gama feshi shi kaɗai.Don haka idan kuna son a gama dashboard ɗin filastik ɗinku cikin launi amma har yanzu kuna da zurfi da haske na gamawar chrome - zaku iya!

| Tsari | Bayani |

| Tsari / es Plastic Chromeing Process/es don sassan da ba na ƙarfe ba (da waɗanda ba ABS*) ba | Tsarin ƙarfe na farko.Sa'an nan "Triple Chrome" plated. Ƙarshen chrome na madubi. Ƙarfin jan ƙarfe, nickel, tsarin chrome |

| Tsari don ABS * robobi | Tsarin shiri na musamman, sannan 'Triple Chrome' plated.Ƙarshen chrome na madubi. Ƙarfin jan ƙarfe, nickel, tsarin chrome. |

| Vacuum Coating (Vacuum Metallising) | Rufin "kamar chrome" (ba chrome na gaske ba) ta hanyar fasaha mara amfani. Ƙarshe mai haske, bakin ciki, azurfa. Rufin bango na bakin ciki - zai iya zama mai lalacewa.Maiyuwa ya isa ga wasu dalilai. |

| Fesa chrome | Fentin (dangane da matasan fenti & kammala sinadarai). Zai iya zama kusanci kusa da chrome amma yana da sauƙi ga bambance-bambance saboda haɗuwar launi da hanyoyi. Dorewa yayi kama da fenti guda 2. |

Tsarin Plastics Plastic Chrome

Mataki na 1 - Etching.Muna nutsar da sashin a cikin tanki wanda ya ƙunshi cakuɗen sulfuric da chromic acid.

Mataki na 2 – Neutralization.

Mataki na 3 - Haɗawa da Haɗawa.

Mataki na 4 - Rashin Electro-less Plating.

Mataki na 5 - Electro Plating.

Mataki 6 - Ingancin Inganci.

chrome na gaske, tabbas kuna iya gogewa da yashi don dawo da ƙarshen.chrome na karya (fim ɗin filastik ko chrome plated) ana iya goge shi, amma a cikin mafi kyawun salon.

Kamar karfe,filastik kuma na iya zama chrome plated.Don wannan hanyar, dole ne ku aika da sassan filastik da kuke son ƙara chrome zuwa ga plating.Thekamfanin platingzai sanya sashin ku a cikin yadudduka na nickel da tagulla kafin ya shafa chrome.